Aluminum alloy is a lightweight and high-strength metal material, it is increasingly applied in industries such as automotive, aerospace, electronics, battery manufacturing, and construction. Especially with the development of vehicle lightweighting and new energy vehicles, the demand for aluminum alloy welding is rapidly growing. However, the unique physical properties of aluminum alloys present significant welding challenges: high thermal conductivity and high reflectivity often cause porosity and cracking during welding, making traditional MIG/TIG welding difficult to achieve high-quality results.

At this point, laser welding aluminum alloy shows unique advantages. With high-power fiber lasers and precise energy control, laser welding machines can achieve stable, precise, and highly efficient welding, significantly improving product performance and production efficiency. Therefore, aluminum laser welding applications have become an important focus for industry research and manufacturing upgrades.

Aluminum Laser Welding

ZS Laser Recommended Laser Welding Machines

To meet diverse aluminum alloy welding needs, ZS Laser recommends the following efficient and reliable welding equipment:

1. Handheld Laser Welding Machine (1500W / 2000W)

Power Range: 1500W and 2000W, select the appropriate power based on the thickness of the aluminum alloy being welded.

Applications: Welding of medium-thin plates such as aluminum alloy doors and windows, automotive parts, and electronic housings.

Features: Flexible operation, fast welding speed, and smooth, aesthetically pleasing welds.

Consulting Service: For detailed configuration and power selection, please contact us for professional advice.

Handled Laser Welder

2. CNC Laser Welding Machine

Functional Configuration: Customizable fixtures and welding platforms are available based on the welding product, supporting multi-torch collaborative welding, significantly improving production efficiency.

Applications: Large-scale production of aluminum alloy structural parts, automotive parts, battery modules, and other batch welding needs.

Features: High-precision CNC control and a high degree of automation, suitable for integration into industrial production lines.

Consulting Service: Customizable power and platform size are available. Please contact us for the optimal solution.

CNC Laser Welding Machine

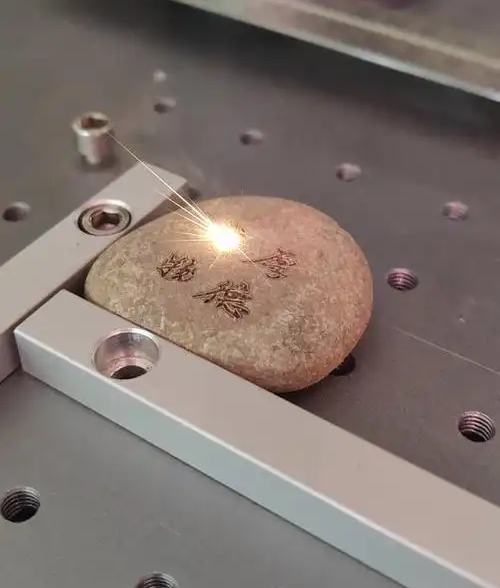

3. Pulse Laser Welding Machine

Professional Design: Designed specifically for lithium battery welding, utilizing pulsed laser technology.

Equipment Options: Available as either a handheld or platform-based automatic welder, flexibly adapting to diverse production needs.

Features: Small heat-affected zone and precise welding, particularly suitable for thin plates and tiny welds.

Applications: High-precision welding for power batteries, consumer electronics batteries, and energy storage batteries.

Pulse Spot Laser Welding Machine

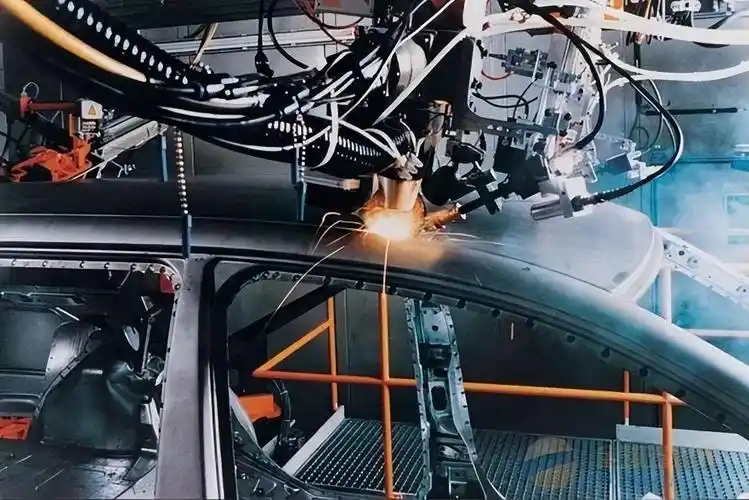

4. Robotic Laser Welding Machine

Functional Configuration: Fully automatic robotic arm, capable of integration into production lines for large-scale continuous production.

Applications: Welding of automotive bodies, aircraft frame structures, and large aluminum alloy parts for shipbuilding and industrial applications.

Features: High precision, strong repeatability, and automated operation significantly improve productivity and consistency.

Consulting Services: Customizable welding paths, power, and fixture configurations to meet the needs of individual production lines.

Robot Welding Machine

Characteristics of Aluminum Alloy and Welding Challenges

Aluminum alloy is a lightweight yet high-strength metal widely used in automotive, aerospace, and electronic manufacturing. However, its specific physical properties make welding challenging—these aluminum alloy welding challenges have long been a focus in the industry.

High Reflectivity

Aluminum surfaces have extremely high reflectivity for laser wavelengths, especially in the near-infrared range. This makes it difficult for laser energy to be effectively absorbed at the beginning of welding, resulting in an unstable molten pool and increased process control complexity.

High Thermal Conductivity

The thermal conductivity of aluminum is much higher than that of steel, causing heat to dissipate rapidly during welding. This can result in insufficient penetration and discontinuous welds. The instability of the molten pool is a key factor contributing to welding defects.

Large Thermal Expansion Coefficient

Aluminum undergoes significant volume changes during heating and cooling, making it prone to deformation, residual stress, and cracking during welding. This is particularly critical for thin sheets and high-precision components.

These difficulties in welding aluminum mean that traditional methods like MIG/TIG welding often fail to meet high-quality requirements.

Typical issues include:

Severe porosity: Hydrogen entrapment can form pores within the weld, reducing strength and density.

Low efficiency: Traditional arc welding produces a large heat-affected zone and slower welding speed, making it difficult to meet modern industrial batch production needs.

Insufficient precision: MIG/TIG welding on complex or thin aluminum structures may cause deformation, failing to meet both appearance and mechanical requirements.

Overcoming these challenges is key to advancing aluminum alloy welding processes, and laser welding has emerged as an optimal solution.

How Laser Welding Machines Overcome Aluminum Alloy Challenges

With the continuous development of laser welding technology for aluminum, laser welding machines have become the ideal solution for aluminum alloy welding challenges. Compared with traditional methods, lasers offer clear advantages in energy efficiency, weld stability, and weld quality. The following methods are particularly effective:

High-Power Fiber Lasers

Using fiber laser welding aluminum technology significantly increases the absorption of laser energy on aluminum surfaces. High-power density laser beams quickly melt the material to form a stable molten pool, avoiding insufficient penetration or discontinuous welds caused by inadequate energy.

Waveform Control and Pulsed Laser

Precise control of laser power waveform or using pulsed laser mode reduces hydrogen retention, lowering the probability of porosity formation. Pulsed lasers also reduce heat input, minimizing the heat-affected zone and lowering the risk of cracking.

Oscillating Welding Process

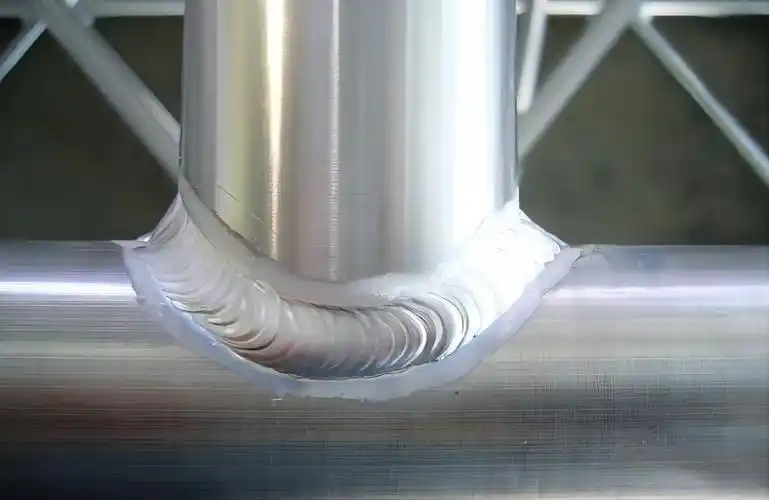

Introducing oscillation (such as figure-eight or circular trajectories) during welding improves molten pool fluidity, resulting in more uniform and full welds. This method increases welding strength and optimizes weld formation quality, making it suitable for thin sheets and complex aluminum parts.

Shielding Gas and Filler Materials

Introducing high-purity argon, helium, or other shielding gases reduces oxidation and improves weld surface finish. Where necessary, filler materials can also enhance weld strength and overall performance.

Through these methods, laser welding machines overcome aluminum alloy challenges, including high reflectivity, high thermal conductivity, and susceptibility to deformation, while achieving higher efficiency and quality. This provides reliable solutions for automotive manufacturing, aerospace, and battery packaging industries.

Aluminum Car Door Laser Welding

Main Applications of Aluminum Laser Welding

Laser welding machines, with high precision, low heat-affected zones, and excellent weld quality, are widely used in various industries. Especially in automotive aluminum welding, aerospace, and battery manufacturing, laser welding demonstrates significant advantages.

Automotive Industry

With lightweighting becoming a global automotive trend, aluminum alloys increasingly replace traditional steel. Laser welding efficiently joins automotive components with high-strength and aesthetically pleasing welds.

Welding aluminum doors, frames, and chassis components reduces overall vehicle weight and improves fuel efficiency.

Aluminum battery welding is widely used in new energy vehicles for battery boxes, cooling components, and battery module packaging, ensuring safety and reliability.

Aerospace

The aerospace industry demands lightweight and high-strength materials. Aerospace aluminum laser welding meets requirements for aircraft skins and structural components.

Laser welding ensures smooth surfaces and low residual stress, extending service life.

High-precision processing allows welding of complex curved parts, improving assembly efficiency and safety.

Electronics and Electrical Industry

Aluminum alloys are widely used in electronics for conductivity and heat dissipation. Laser welding ensures high-quality connections for small components.

Welding aluminum heat sinks, housings, and conductive elements prevents cold joints and thermal damage.

Suitable for high-density electronic devices, ensuring stable performance.

Construction and Industrial Equipment

In construction and industrial applications, aluminum is used for structural and decorative components. Laser welding provides efficient and durable joining.

Welding aluminum doors, windows, curtain walls, and panels achieves both aesthetics and durability.

Welding aluminum pipelines and frames in industrial equipment ensures strength and longevity.

By deeply integrating into these industries, laser welding not only promotes lightweight and intelligent manufacturing but also provides efficient and eco-friendly aluminum processing solutions.

Advantages of Using Laser Welding Machines for Aluminum

Compared to traditional MIG/TIG welding, laser welding offers significant advantages when processing aluminum alloys. These advantages of laser welding aluminum alloy make it a preferred choice for automotive, aerospace, electronics, and construction industries.

High Precision and Aesthetic Welds

Laser welding uses focused beams for high precision aluminum welding, controlling welds at the micron level. Welds are smooth and even, requiring minimal post-polishing, making it ideal for products with high aesthetic requirements.

High Speed and Efficiency

High energy density allows laser welding to achieve speeds far exceeding traditional methods, significantly improving productivity. Stable processing quality is maintained for both custom and batch production.

Small Heat-Affected Zone, Reduced Deformation

Due to aluminum’s high thermal expansion, traditional welding often causes deformation. Laser welding, with high energy density and very short interaction time, minimizes the heat-affected zone, reducing deformation, stress, and cracking.

Supports Dissimilar Metal Welding

Laser welding can process pure aluminum, aluminum alloys, and aluminum-to-other-metal joints (such as copper or steel). This expands possibilities for battery manufacturing, electronic components, and structural parts, increasing process flexibility and applicability.

Future Development Trends

As laser welding technology continues to evolve, aluminum processing faces new opportunities. The future of aluminum laser welding focuses on:

Laser + AI Quality Monitoring

AI-driven real-time weld monitoring and automatic defect detection enhance consistency and reliability. Adaptive parameter optimization reduces manual intervention.

Digital Twin and Smart Manufacturing

Integrating with smart manufacturing aluminum welding technology, companies can simulate welding processes in virtual environments, predict potential issues, and optimize production plans, significantly improving efficiency and precision.

Higher Power and Ultrafast Laser Applications

Next-generation high-power and ultrafast pulsed lasers show tremendous potential in deep-penetration and high-precision aluminum welding, potentially overcoming limitations in thick plates and complex structures.

ZS Laser Solutions

ZS Laser provides industry-leading aluminum laser welding solutions, with customizable power, operation modes, and automation levels. Whether for small-scale R&D or large-scale production, we deliver efficient and reliable laser welding equipment.

Get a free welding sample test

Contact us for customized aluminum laser welding solutions

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.