In recent years, laser marking technology has been widely applied in both the manufacturing and consumer goods industries. However, when the processing material is glass—a transparent and brittle material—the difficulty of processing increases significantly. Glass has high light transmittance and fragility. Conventional lasers often struggle to focus on its surface, leading to energy penetration or localized stress concentration, which can cause cracks or even breakage. This makes laser marking on glass and glass engraving technologies that place extremely high demands on equipment performance and process parameters.

Below, ZS Laser will explore in depth the technical principles, processing challenges, and solutions of glass laser marking, and, combined with practical application scenarios, demonstrate the value and potential of this advanced process in modern manufacturing and personalized customization.

Glass Laser Marking

The Uniqueness of Glass Laser Marking

Special Properties of Transparent Materials

As a transparent material, glass has extremely high light transmittance. When exposed to a conventional laser, the energy tends to disperse or penetrate, resulting in blurred marking effects or even ineffective etching. Traditional marking methods such as inkjet printing and screen printing can leave patterns on the glass surface, but they commonly suffer from fading, poor wear resistance, and weak adhesion, which fail to meet the requirements of durability and aesthetics.

To address this, modern glass laser marking generally uses short-pulse lasers (such as green lasers and UV lasers). Their wavelengths are more easily absorbed by glass, allowing for micron-level modification on the surface or near-surface, achieving permanent marks without affecting transparency.

Advantages of Non-Contact Processing

Glass is a brittle material. Traditional mechanical engraving can easily cause cracks, chips, or stress concentration, which negatively impact yield. Laser marking, however, is a non-contact process. It does not require tools or consumables, and instead uses a focused laser beam to induce physical or chemical changes on the glass surface, avoiding damage to the material itself.

Precision and Aesthetics

Compared with traditional processes, laser marking can achieve micron-level engraving on glass surfaces. Whether for brand logos, QR codes, or personalized designs, the results have sharp edges and high-contrast effects. More importantly, laser marking does not compromise the overall transparency of the glass, balancing both functionality and aesthetics.

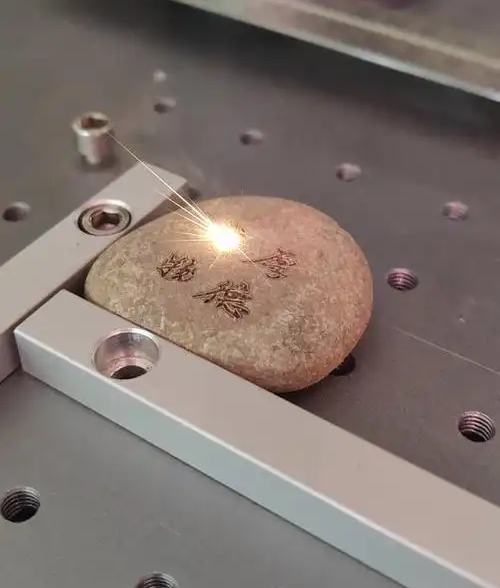

Glass Laser Marking Sample

Challenges and Solutions in Transparent Material Marking

Key Challenges

Laser Energy Penetration

Due to the high light transmittance of glass and other transparent materials, conventional laser beams tend to pass directly through, making it difficult to concentrate energy on the surface. This results in shallow markings and blurred effects.

High Fragility of Glass

As a brittle material, glass is prone to micro-cracks, chipping, or stress concentration if excessive heat builds up during processing. In severe cases, the entire glass piece may fracture, lowering yield.

Insufficient Engraving Contrast

Even when a mark is formed on the glass surface, low contrast may make text, patterns, or QR codes difficult to read, especially against a transparent background. This reduces practical usability.

Solutions

Selecting the Right Laser Wavelength

Compared with common fiber lasers, UV lasers (355 nm) and green lasers (532 nm) are better suited for transparent materials. Their shorter wavelengths are more readily absorbed by glass, reducing penetration and improving surface modification, thereby achieving clear and durable markings.

Precise Control of Power and Pulse Width

By carefully adjusting laser power, pulse width, and scanning speed, heat accumulation can be minimized, reducing the risk of thermal cracks and stress concentration, and ensuring a smooth, intact glass surface.

Front/Backside Marking Techniques

Surface engraving can be done on the front side of the glass, while backside marking can create “relief” or suspended effects inside the glass. This not only enhances visual appeal but also keeps the front surface smooth and intact.

Auxiliary Processes to Improve Contrast

Before marking, applying surface coatings, films, or specialized absorption layers can enhance laser absorption and increase marking contrast. After processing, the coating is removed, leaving behind a clear and durable engraving.

Major Applications of Glass Laser Marking

Wine Bottles and Beverage Containers

In the wine and premium beverage industries, laser marking on glass has become an important tool for enhancing brand image and anti-counterfeiting. Lasers can engrave brand logos, production dates, batch numbers, or QR codes on bottle surfaces. These marks are not only clear and permanent but also resistant to tampering and wear.

Laser technology also supports personalization, such as engraving custom text or patterns on commemorative bottles or gift packaging. This enhances brand differentiation and market recognition. Compared with traditional inkjet printing, glass engraving is more attractive, environmentally friendly, and durable.

Laboratory Glassware

Laboratory environments require markings with exceptional durability. Laser marking can engrave graduations, serial numbers, and batch identifiers on beakers, test tubes, and pipettes, ensuring legibility even after repeated cleaning, high-temperature sterilization, and chemical exposure.

Such permanent markings not only extend the service life of the glassware but also help researchers maintain efficient sample management and traceability during experiments.

Touchscreens and Electronic Glass

In the electronics industry, glass is widely used in touchscreens, displays, and sensor panels. Laser marking can achieve highly precise logo engraving and functional markings (such as circuit pathways or sensor regions), maintaining clarity and consistency at the micron scale.

Moreover, since the process is non-contact, it does not cause mechanical damage or contamination on the glass surface. This ensures both aesthetic quality and the functional requirements of high-end electronic products.

How to Choose the Right Glass Laser Marking Machine

When considering laser marking on glass or glass engraving, choosing the right equipment is crucial. Based on over ten years of experience in laser marking equipment, ZS Laser recommends the following:

UV Laser Marking Machine: Short wavelength, ideal for transparent glass. It minimizes thermal effects and produces higher contrast engravings. Commonly used for wine bottles, laboratory glassware, and electronic glass.

Fem to second Laser Marking Machine: With ultrashort pulses and virtually no thermal effect, it achieves nanometer-level precision, making it perfect for high-end applications with strict requirements for crack prevention and aesthetics.

UV Laser Marking Machine

Key Configurations to Consider

Power: Determines marking depth and speed. Should be selected based on glass thickness and application needs.

Cooling System: A water-cooling system ensures stable performance during long-term operation.

Software Compatibility: Compatibility with CAD, CorelDRAW, and other software allows quick import of complex patterns and QR codes.

Production Requirements

Small-Batch Customization: Suitable for crafts, personalized gifts, and laboratory glassware.

Mass Production: Suitable for beverage bottles and electronic glass. For these, automated marking machines that can be integrated into production lines are recommended to improve efficiency and consistency.

If You Are Looking for a Professional Glass Laser Marking Solution:

Get customized equipment recommendations tailored to your industry

Schedule a free sample marking test to experience the results firsthand

Consult with our technical team to determine whether UV laser or femtosecond laser equipment best suits your needs

Contact us today and upgrade your glass processing with ZS Laser—adding more value and competitiveness to your products!

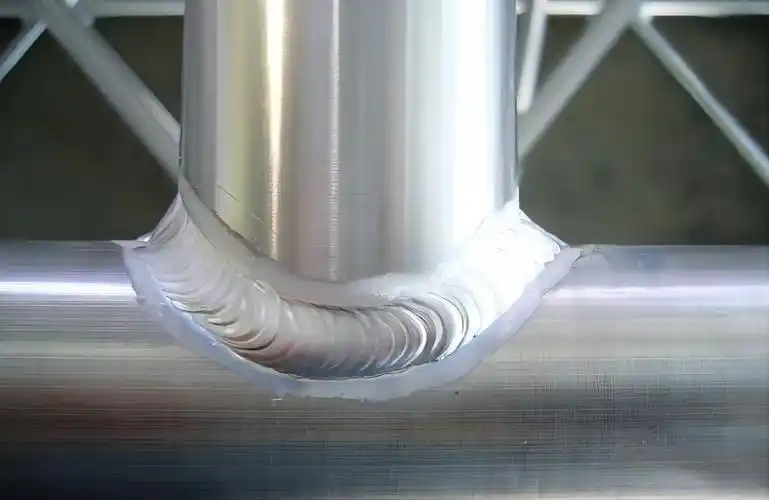

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.