In the defense industry, the traceability, reliability, and anti-counterfeiting of equipment and components are essential to ensuring national security and supply chain transparency. In particular, the management of guns and ammunition relies heavily on marking technology, which directly impacts production traceability, inventory control, forensic identification, and accountability.

Traditional methods such as mechanical engraving or inkjet coding often suffer from unclear marks, wear and tear, or susceptibility to tampering, making them unable to meet today’s stringent safety and compliance requirements. Laser marking, as a high-precision and permanent marking technology, is gradually becoming the preferred tool in the defense sector. It plays an irreplaceable role in gun marking, ammunition marking, and the identification of military components.

Laser Marking On Guns

Application Scenarios of Gun and Ammunition Marking

Gun Marking

In defense and law enforcement systems, each gun must carry a unique identity mark to trace its manufacturer, model, batch, and usage history.

Laser marking can be applied to the following areas:

Barrel and receiver: Engraving serial numbers, model, and manufacturer information.

Critical components: Such as micro-codes on the trigger or safety, enabling internal traceability.

QR codes or micro-engraved codes: Supporting digital management and seamless integration with databases.

This form of gun marking not only enhances traceability and accountability but also provides vital information in cases of accidents or loss.

Ammunition Marking

Ammunition marking is primarily applied to cartridge cases and primers, where laser etching can imprint batch numbers, production dates, or invisible codes to establish anti-counterfeiting and traceability systems.

Batch management: Enables rapid distinction between production batches in mass manufacturing.

Forensic support: Codes on bullets assist in ballistic analysis, improving the efficiency of evidence collection.

Anti-counterfeiting and traceability: Prevents illegal ammunition from entering the market and ensures supply chain compliance.

By implementing both gun marking and ammunition marking, defense departments can establish a comprehensive life cycle traceability system for weapons and ammunition.

Bullet laser marking

Marking Content and Traceability System

In defense applications, laser marking goes beyond physical marks—it also serves as an interface for digital management.

Marking content: Serial numbers, batch numbers, manufacturer details, certification marks, QR codes/Datamatrix, etc.

Database integration: Marking data can be linked with ERP and WMS systems, enabling closed-loop traceability from production to storage and use.

Blockchain applications: In the future, blockchain can be leveraged to create tamper-proof traceability records for defense materials.

Material and Process Adaptability

Defense equipment involves a wide range of materials:

Steel and stainless steel: Commonly used in barrels and bolts.

Aluminum alloys: Widely applied in lightweight weapon attachments.

Brass: Used in cartridge cases.

Laser marking systems can select the appropriate laser type based on the material (e.g., fiber lasers for metals) to ensure clear and durable marks. Additionally, laser technology can mark coated or plated surfaces, ensuring reliability even in harsh environments.

Regulatory Compliance and Anti-Counterfeiting Identification

In the defense sector, marking is not only a management tool but also a requirement for compliance and security:

Regulatory requirements: Many countries impose strict legal standards for gun and ammunition marking; laser marking helps manufacturers meet these regulations.

Anti-counterfeiting functions: Micro-codes or invisible marks effectively prevent illegal replication and tampering.

Forensic identification: Laser marking data combined with ballistic traces aids forensic experts and law enforcement in quickly identifying the source of guns and ammunition.

Production Line Integration and Quality Control

Modern defense manufacturing emphasizes large-scale and automated production. Laser marking can be deeply integrated into production lines:

Automated fixtures and robotic arms: Enable high-speed, assembly-line marking.

Vision inspection systems: Verify marking clarity and accuracy in real time.

Data recording: Every marking operation can be archived automatically, serving as a basis for auditing and regulatory oversight.

This integration significantly improves efficiency and management, meeting the demands of large-scale defense manufacturing.

Future Development Trends

With the advancement of Industry 4.0 and smart manufacturing, laser marking in the defense industry is set for further upgrades:

AI monitoring: Artificial intelligence can identify marking defects and perform automatic corrections.

Broader material adaptability: Future technologies may enable precise marking on dissimilar metals and even composite materials.

Micron- and nano-scale marking: Ultrafast laser technology can achieve extremely fine marks, enhancing anti-counterfeiting measures.

Blockchain and digital twins: Combined with digital twin systems, this can establish a transparent, full-lifecycle traceability system.

Conclusion and Recommended Solutions by ZS Laser

As a high-precision and reliable technology, laser marking is profoundly transforming defense industry production and management. From gun marking to ammunition marking, it not only enhances traceability and anti-counterfeiting but also provides strong support for forensic identification and supply chain compliance.

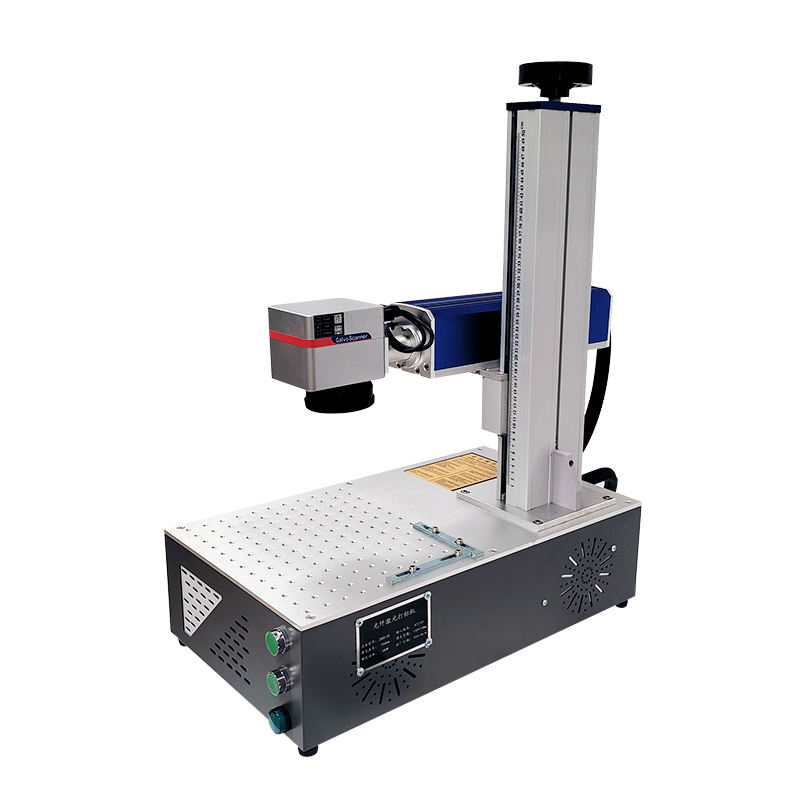

At ZS Laser, we recommend two types of fiber laser marking machines that are especially suitable for defense industry applications:

Handheld Fiber Laser Marking Machine

Ideal for marking large or immovable defense equipment. This portable design allows operators to perform gun marking or component marking directly on-site without the need to move heavy objects. It ensures flexibility and efficiency in handling oversized or irregularly shaped military assets.

Flying Fiber Laser Marking Machine

Designed for high-speed and continuous ammunition marking and large-scale gun component marking. It can be seamlessly integrated into existing production lines, enabling automated, efficient, and precise marking for mass manufacturing in the defense sector.

Both machines leverage the advantages of fiber laser technology—high precision, durability, and adaptability to a wide range of metals such as steel, aluminum alloys, and brass—ensuring that marks remain clear and permanent, even under extreme conditions.

Portable Fiber Laser Marking Machine

Compact and lightweight, perfect for field operations or environments where mobility is critical. It is well-suited for on-site gun marking or ammunition batch coding, providing high flexibility while maintaining precision.

Portable Fiber Laser Marking Machine

If you are seeking defense-grade laser marking solutions, ZS Laser offers free sample marking tests, technical consultation, and customized system design to help you build a safer, more efficient marking management system that meets both compliance and innovation requirements.

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.