Our 1500W laser welding machine starts at $2,599 USD, and the price will vary depending on the machine configuration, degree of automation, laser power, worktable size, and other additional options.

The 1500W laser welding machine is a medium-power laser welding system designed to deliver precise, high-quality welds on a variety of metal materials. Its power level strikes a balance between performance and cost, making it a popular choice for small and medium-sized enterprises (SMEs). For many companies, the 1500W laser welding machine offers a combination of accuracy, versatility, and affordability, allowing them to produce high-quality welded components without investing in larger, more expensive high-power systems.

1500W Handled Laser Welding Machine

What Makes 1500W Special?

Among the range of available laser powers, the 1500W laser welding machine occupies an optimal balance point, providing an excellent combination of performance, efficiency, and cost. Its moderate power is sufficient to achieve deep and reliable welds without consuming excessive energy, making it an ideal choice for applications that require both precision and productivity.

This power level is well-suited for most common metals, such as stainless steel and carbon steel, typically in thicknesses ranging from 0.8 to 5 mm. It can efficiently handle medium-thickness sheets and tubes, delivering consistent welding quality across a variety of applications. Compared to high-power systems, 1500W machines have lower upfront investment and maintenance costs, making them a practical option for SMEs seeking high-quality results on a budget.

At the same time, they outperform lower-power machines in welding speed and penetration, ensuring efficient processing and strong, stable welds. The combination of affordability, versatility, and adequate power makes the 1500W laser welding machine a reliable choice across many industries.

How a 1500W Laser Welding Machine Works

The 1500W laser welding machine works by focusing a high-energy laser beam onto the metal surface, generating intense heat at precise points. This energy locally melts the metal, allowing it to fuse seamlessly with other components in many cases without additional filler material. The focused heat minimizes the heat-affected zone (HAZ), reducing warping, distortion, and post-weld finishing.

Unlike traditional welding methods such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding, laser welding delivers energy at high precision and speed. TIG and MIG rely on an electric arc to melt the metal, creating a larger HAZ and slower welding speed, whereas a 1500W laser system produces uniform, narrow welds with stable quality. This makes it ideal for thin sheets, small components, and complex geometries, where traditional methods struggle to maintain consistent welds.

Additionally, laser welding machines are compatible with automation systems, allowing integration with robots for continuous production. This enables SMEs to achieve high productivity and repeatable results without increasing labor costs.

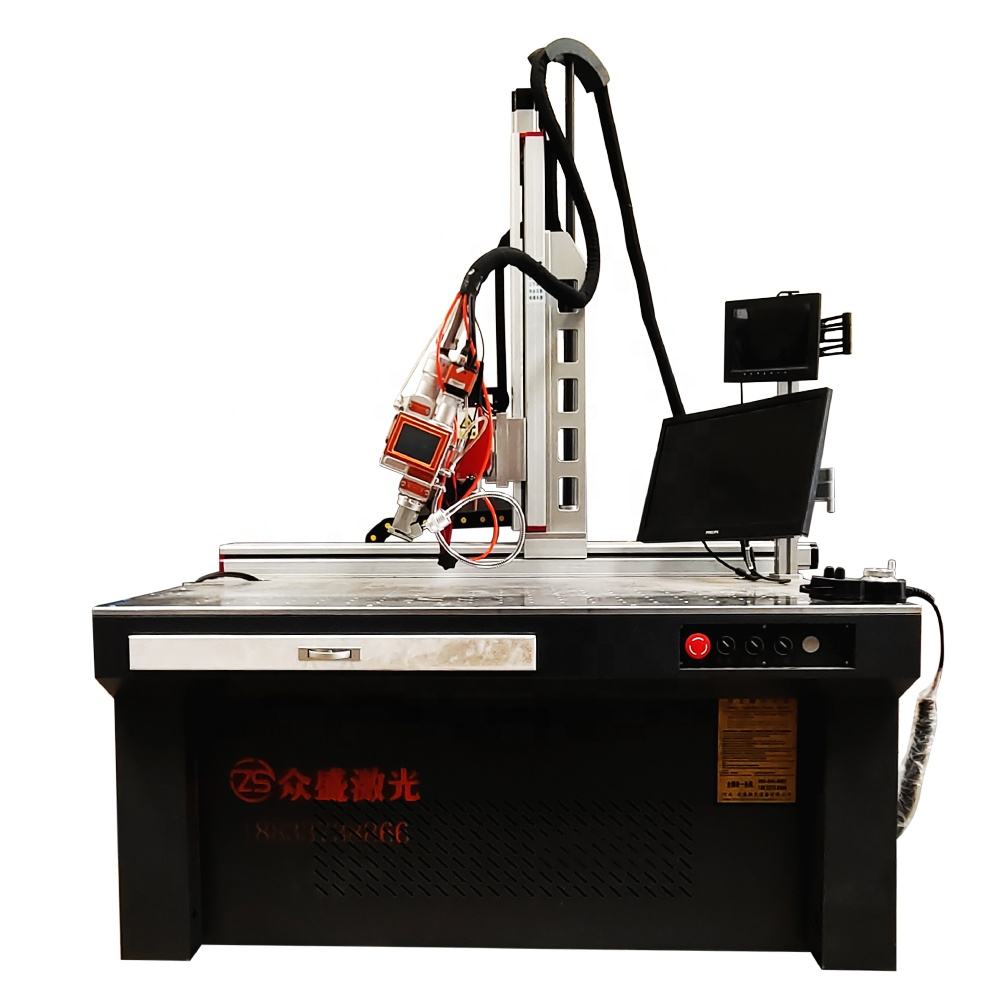

1500W Automatic Laser Welding Machine

Unique Advantages of 1500W Machines

Cost-Performance Sweet Spot

1500W laser welding machines strike a perfect balance between price and performance, providing a cost-effective solution for SMEs engaged in batch production. They deliver strong performance without the large investment required for higher-power systems.

Material Versatility

This power level is suitable for common medium-thickness metals such as stainless steel, carbon steel, and aluminum alloys. It can handle welding tasks ranging from thin sheets to medium-thickness components, making it adaptable to various manufacturing applications.

Flexible Configurations

1500W machines are available in handheld, semi-automatic, fully automatic, and robotic configurations, giving manufacturers the flexibility to choose a system that matches their production scale and workflow requirements.

Energy & Heat Management

With moderate laser power, 1500W machines provide sufficient weld penetration while controlling the HAZ. This reduces the risk of warping, deformation, and post-weld rework, ensuring consistent, high-quality results.

The combination of affordability, versatility, and controlled heat impact makes the 1500W laser welding machine a practical and reliable choice for many industries.

Typical Applications of 1500W Laser Welding Machines

Automotive Components

Ideal for welding thin metal sheets and tubular parts such as chassis components, brackets, and exhaust parts, where precise and consistent penetration is required.

Furniture & Kitchenware

Suitable for metal frames, handles, and structural parts in furniture, kitchen utensils, and decorative items, delivering clear welds with minimal distortion.

Small Machinery & Industrial Parts

Applicable to small machinery components, industrial fittings, and custom equipment parts, providing reliable strength and accuracy for repeat production.

Maintenance & Prototyping

Excellent for maintenance, repair, and prototyping tasks that require flexibility, fast setup, and cost-effective operation without the need for high-power industrial systems.

This versatility makes the 1500W laser welding machine a practical choice across industries, combining efficiency, precision, and affordability.

Choosing the Right 1500W Laser Welding Machine

Selecting the ideal 1500W machine depends on several factors, including production scale, material type, workpiece thickness, and required level of automation.

Production Scale:

Small-scale or low-volume operations may benefit from handheld or portable 1500W systems, offering flexibility and easy setup.

Medium-scale production often prefers semi-automatic systems, balancing stable weld quality with moderate automation to increase output without excessive investment.

High-volume production typically requires fully automatic or robotic 1500W welding systems for continuous operation, high precision, and minimal manual intervention.

Material Type & Thickness:

1500W machines are well-suited for welding common metals like stainless steel, carbon steel, and aluminum, with thicknesses generally from 0.8 mm to 5 mm, depending on settings. Choosing the right system ensures optimal weld penetration, minimal heat distortion, and high-quality, repeatable results.

Automation Needs:

Assess whether your workflow requires manual operation, partial automation, or fully integrated robotic systems. ZS Laser offers flexible configurations to meet these needs, from handheld devices to customized robotic setups for high-efficiency production lines.

ZS Laser Solutions

ZS Laser provides a range of 1500W laser welding machines designed for different applications. Customers can choose handheld, semi-automatic, or fully automatic systems, equipped with customizable fixtures, multi-head options, and integrated control systems. This ensures that each client receives a solution that meets their production requirements, budget, and expected efficiency, while retaining the high precision and reliability of a 1500W system.

By carefully evaluating your production needs and selecting the right configuration, ZS Laser’s 1500W laser welding machines offer an optimal balance of cost-effectiveness, performance, and versatility.

For more information on how a 1500W laser welding machine can improve your production efficiency while maintaining high-quality results, contact ZS Laser today. Our team can provide consultation, sample welding tests, and customized solutions tailored to your specific manufacturing needs.

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.