In today’s fast-paced manufacturing environment, product marking has become a critical step for traceability, branding, and compliance.

From barcodes and QR codes to serial numbers and logos, clear and durable marks ensure smooth circulation of products throughout the supply chain. The flying laser marking machine is specifically designed for continuous high-speed marking, allowing products to be marked while moving — ensuring uninterrupted production.

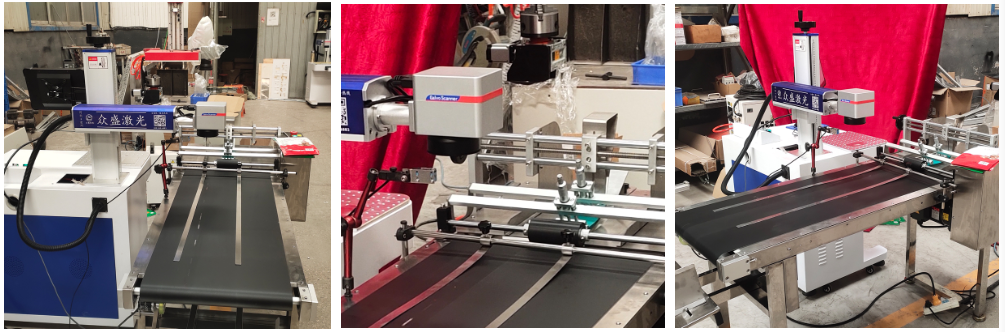

Flying CO2 Laser Marking Machine

What is a Flying Laser Marking Machine?

A flying laser marking machine is a laser system designed for high-speed, continuous production lines. During the marking process, it synchronizes with the movement of products on the conveyor, enabling real-time marking while products are in motion.

The key advantage of this technology lies in its non-stop operation. Since there is no need to pause production for marking, it significantly boosts efficiency and throughput, making it ideal for large-scale, high-volume industries.

Compared with traditional static laser marking machines, flying laser markers offer:

Continuous operation – products are marked without halting production.

Higher efficiency – reduced downtime and faster production line speed.

Increased productivity – consistent, high-quality results suitable for mass production.

This makes flying laser marking an indispensable solution in modern manufacturing, where both speed and precision are critical.

Why Choose CO₂ Lasers as the Light Source?

When it comes to flying laser marking machines, the choice of laser source is crucial. For applications involving non-metal materials, CO₂ lasers are often the best option.

Broad Material Compatibility

CO₂ lasers can efficiently mark plastics, glass, wood, leather, paper, textiles, and many other non-metallic materials. This versatility makes them ideal for packaging, consumer goods, and multi-material industrial applications.

Cost-Effective Solution

Compared with fiber lasers, CO₂ lasers provide a more economical choice for large-scale non-metal marking. Businesses can achieve high-quality results without the higher upfront cost of fiber systems.

Stable and Reliable

With decades of proven market performance, CO₂ lasers are renowned for their long lifespan, stable output, and low maintenance requirements — ensuring reliable operation even under demanding conditions.

Eco-Friendly and Efficient

CO₂ laser marking is a clean process — no inks, solvents, or consumables are required, and no chemical waste is produced. It’s both environmentally friendly and cost-saving in the long run.

Flying CO2 Laser Marking Machine

Applications of Flying CO₂ Laser Marking Machines

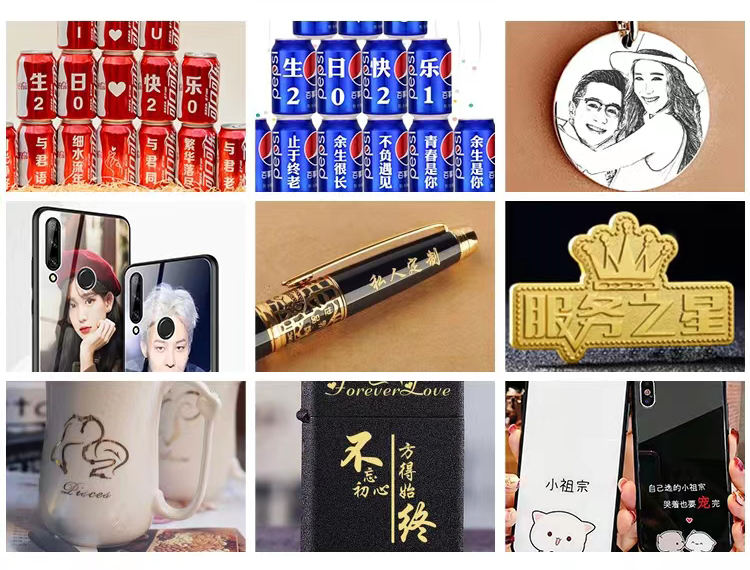

Flying CO₂ laser marking machines are widely used across industries thanks to their ability to deliver high-speed, precise, and permanent marks on a variety of non-metallic materials.

Packaging Industry

Ideal for marking barcodes, QR codes, expiration dates, and batch numbers directly on cardboard, plastic films, or labels — ensuring traceability and compliance.

Automotive Industry

Commonly used to mark plastic parts, rubber hoses, and interior components. The marks remain clear and withstand wear, heat, and long-term usage in vehicles.

Electronics Industry

Ensures precise, high-contrast marks on PCBs, plastic housings, and connectors. These markings are critical for quality control, traceability, and compliance with manufacturing standards.

Textiles & Leather

Perfect for engraving logos, decorative patterns, and brand marks on fabrics, leather goods, and garments — combining functionality with branding.

Pharmaceutical Industry

Provides reliable marking for packaging, anti-counterfeit labels, and medical devices. Permanent, precise marks ensure safety, authenticity, and compliance with strict regulations.

Matching the Right Laser Source to Your Product

At ZS Laser, our laser marking machines are designed with flexibility, allowing customers to choose the most suitable laser source based on their materials and production needs.

CO₂ Lasers

The preferred choice for non-metallic materials such as plastics, glass, wood, paper, textiles, and leather. CO₂ lasers are economical, reliable, and perfect for high-speed marking in packaging and consumer goods.

Fiber Lasers

Ideal for metals and certain plastics, delivering deep, durable, high-contrast marks. A top choice for industries like automotive, electronics, and machinery, where durability and traceability are critical.

UV Lasers

Designed for ultra-fine, high-resolution marking, especially suitable for sensitive materials such as medical plastics, electronic components, and specialty packaging. UV lasers provide clear micro-marking without damaging delicate substrates.

ZS Laser integrates only top-tier laser brands such as MAX Photonics, ensuring stability, performance, and long service life. Our technical team also provides customization options — including power ranges, beam spot sizes, software interfaces, and seamless integration with your existing production lines.

With this flexibility, every customer receives a marking solution that not only fits their material requirements but also enhances production efficiency and long-term reliability.

Upgrade Your Production Today

If you’re looking to improve efficiency, reduce costs, and achieve exceptional marking quality, now is the perfect time to upgrade your production line.

Contact ZS Laser today for expert consultation, free sample marking tests, and customized solutions designed to deliver long-term value for your business.

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.