With the growing demand for personalized consumption and high-end decoration, stone processing is entering a new stage of development. Stone, known for its durability and unique textures, is widely used in souvenirs, architectural decoration, and craft gifts. However, traditional engraving methods suffer from low efficiency, limited precision, and restricted design capabilities.

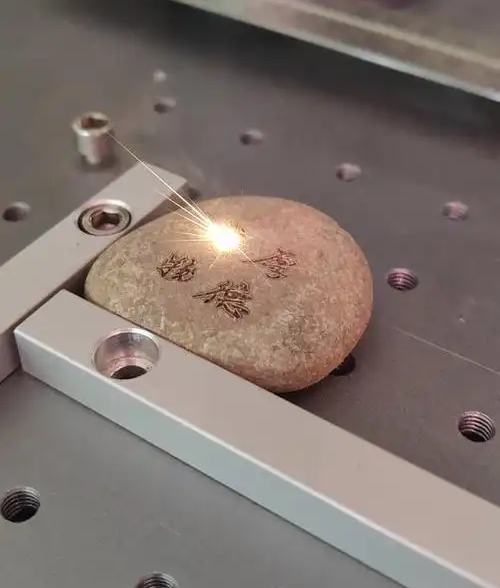

The introduction of laser technology has brought breakthroughs to this field. Laser marking on stone and stone laser engraving not only achieve high-precision, permanent markings but also present exquisite patterns, text, and even complex artistic designs on stone surfaces. This combination of functionality and aesthetics significantly enhances the market competitiveness and commercial value of stone products.

Stone Laser Marking

Characteristics and Processing Challenges of Stone

Stone is a hard, natural material with diverse textures, including granite, marble, jade, shale, and sandstone. Different types of stone vary significantly in hardness, density, and grain structure, directly affecting processing methods and engraving results. For example:

Granite has high hardness and excellent wear resistance but tends to crack during mechanical processing.

Marble has a relatively fine texture but is brittle and sensitive to thermal stress.

Traditional engraving methods, such as manual carving or mechanical cutting, face the following limitations:

Low efficiency: Manual carving is time-consuming, while mechanical tool processing requires multiple passes, making it difficult to meet mass production demands.

Limited precision: Complex patterns or fine text are hard to achieve accurately, often leading to errors.

Material damage: Direct tool contact with stone surfaces can cause cracks, chipping, or surface damage, especially with hard stones.

Design restrictions: Complex artistic textures or gradient effects are difficult to realize with traditional methods.

Laser processing brings significant breakthroughs in stone applications:

Non-contact processing: The laser beam does not physically touch the material, avoiding tool-induced damage.

High precision and controllability: Laser power, pulse width, and scanning speed can be precisely adjusted to achieve micron-level detail on hard stone.

Adaptability to various textures and hardness: Whether granite or jade with complex textures, lasers can ensure stable and uniform marking/engraving results.

Complex design realization: With programmed laser paths, it is easy to produce text, logos, patterns, and even gradient effects, meeting both artistic and commercial needs.

Thus, laser technology not only solves efficiency and precision issues in stone processing but also expands creative possibilities, making carved products both beautiful and durable.

Main Applications of Stone Laser Marking and Engraving

Laser technology demonstrates unique advantages in stone processing, giving stone both decorative and functional/personalized value. Main applications include:

Souvenirs and Gifts

Tombstones and memorial stones: Names, dates, poems, or commemorative designs can be engraved with clarity and permanence.

Plaques and trophies: Designs and inscriptions on stone plaques or commemorative trophies enhance texture and collectible value.

Personalized custom gifts: Customer-specific designs, signatures, or messages can be engraved, making gifts unique.

Crafts and Artworks

Reliefs and patterns: Lasers create detailed reliefs or complex textures on stone surfaces, surpassing traditional precision.

Personalized patterns: Support custom designs from artists or brands, merging creativity with commercial value.

Small crafts: Stone ornaments or jewelry can be finely engraved at small sizes with clear details.

Architecture and Decoration

Tiles, walls, and background panels: Engraved geometric patterns, relief textures, or text for personalized design.

Decorative stone components: Columns, door frames, and window sills can be laser-engraved with exquisite patterns to elevate spatial quality.

Anti-slip and functional marking: Fine textures on tiles or steps combine practicality with aesthetics.

Business and Brand Display

Corporate landmark sculptures: Logos and slogans on large stone carvings in lobbies or campuses showcase brand identity.

Indoor/outdoor branding decorations: Durable, finely detailed laser-engraved stone signs, background walls, or commemorative stones.

Custom display projects: Compatible with various stone materials and complex designs for personalized branding needs.

Through laser marking and engraving, stone processing achieves efficiency, precision, artistry, personalization, and commercial value, playing a bigger role in souvenirs, decorations, and brand displays.

Jade laser engraving

Why Choose Laser Marking for Stone

Laser marking in stone processing offers significant advantages, making it an efficient, precise, and sustainable solution:

High precision and detail reproduction: Achieves micron-level engraving of complex patterns, fine text, or photo-level images with clarity and sharpness—far exceeding traditional mechanical methods.

Permanence and durability: Engravings are wear-resistant and non-fading, suitable for outdoor monuments, architectural decorations, and long-term preserved plaques or gifts.

Non-contact processing: Protects stone integrity by avoiding cracks, chips, or stress damage from tool friction—especially important for brittle stones like marble and jade.

Diverse expression forms: Enables flat marking, relief carving, gradient textures, and photo-like engravings, meeting decorative, artistic, and functional needs.

Eco-friendly and efficient: No inks, chemicals, or consumables required; fast processing and automation support both batch production and custom orders.

Challenges of Stone Laser Marking and Solutions

Although advantageous, stone’s properties create challenges that require technical solutions:

Challenges

High hardness: Different stones vary in hardness, making traditional methods prone to tool wear or cracks; lasers must overcome differences in heat resistance and absorption.

Thermal sensitivity: Stones can develop burn marks, cracks, or debris under heat, especially with deep engraving or high power.

Low contrast engraving: Natural stone textures and colors may reduce pattern clarity and contrast.

Solutions

Proper laser wavelength selection: CO₂ lasers are best for stone, as their wavelength is easily absorbed and allows high-quality engraving while preserving surface integrity. For special stones, multiple wavelengths or pulse modes may be applied.

Precise power and pulse control: Adjusting laser power, scanning speed, and pulse width based on stone hardness and depth ensures smooth edges and clear designs without excessive burning.

Cooling and dust removal systems: Air or water cooling prevents overheating, while dust collectors improve quality, maintain a clean environment, and ensure stable long-term operation.

These methods allow fine engraving on hard stone surfaces while preserving material integrity and aesthetics, making laser marking reliable for souvenirs, decoration, and construction applications.

Laser Marking On Stone

How to Choose the Right Stone Laser Marking Machine

Selecting the right laser marking machine is crucial for ensuring engraving quality, efficiency, and long-term reliability. Key factors include:

Laser type

Due to stone’s hardness and surface variety, CO₂ lasers are preferred as their wavelength is better absorbed by stone. Compared to fiber lasers, CO₂ machines are more suitable for granite, marble, jade, and other hard stones.

Power selection

Low power: For shallow marking or fine designs without surface burning.

Medium to high power: For deep engraving, relief carving, or large-area processing, ensuring consistency and efficiency.

Working area size

Small stones/souvenirs: Desktop machines.

Large stones such as decorative panels, tombstones, or tiles: Large-format workbenches for precise one-pass processing.

Software and compatibility

Must support vector designs, bitmap imports, and batch processing.

Features such as path optimization, depth control, and layout functions improve efficiency.

Machine performance

Durability: High-quality optics and cooling for stable long-term operation.

Speed: High-speed scanning and automation for mass production.

Adjustable power: Flexible for different stone types and engraving needs.

By considering these factors, users can select the most suitable laser machine for their stone processing needs, ensuring beautiful, efficient, and reliable results.

Future Development Trends

With continuous advances in laser and CNC technology, stone laser marking and engraving are evolving toward new innovations:

Integration of laser and CNC technology: Precision CNC motion control combined with lasers enables complex designs, fine lines, and micron-level details previously impossible with traditional methods.

Personalization and small-batch production: Rising demand for unique, customized stone products is making flexible, small-scale production mainstream—well-suited to laser engraving.

Integration with 3D modeling: Combining 3D modeling and laser control allows stereoscopic and relief effects, enhancing artistry and broadening applications in architecture, monuments, and crafts.

These trends show that laser technology is driving stone processing toward high precision, high added value, and intelligent manufacturing, offering businesses new innovation opportunities.

Stone laser marking and engraving technology, with its high precision, non-contact nature, permanence, and versatility, has unique value in crafts, souvenirs, architecture, and branding. Whether for micron-level fine engraving or large-scale relief carving, laser technology provides stable, efficient, and eco-friendly solutions.

ZS Laser is committed to delivering professional and reliable laser stone processing equipment and technical support, helping enterprises achieve high-quality, customized, and innovative production.

👉 Contact us now for tailored stone laser marking and engraving solutions, or book a sample marking/engraving test.

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.