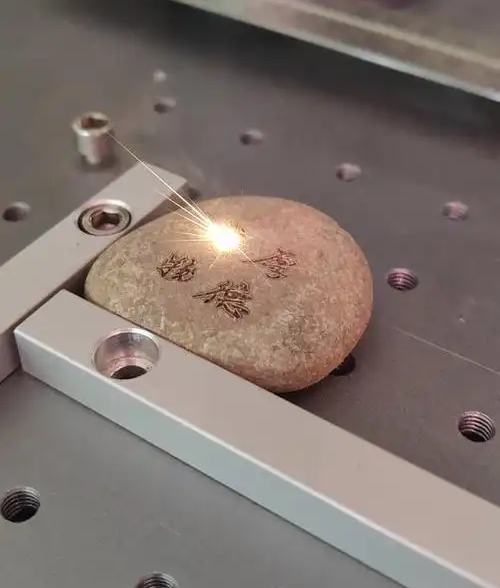

Laser marking and engraving technology has become an essential process in modern manufacturing, widely applied across various materials such as metals, plastics, and glass. With its high precision, permanence, and eco-friendliness, laser technology not only plays a significant role in industrial production but also increasingly penetrates the crafts, gifts, and decoration sectors.

Wood, as a natural material, combines unique textures with a warm, tactile quality and is extensively used in furniture manufacturing, art and crafts, and interior decoration. Traditional carving or printing methods on wood often suffer from insufficient precision, poor durability, and time-consuming processes. The introduction of laser technology effectively addresses these challenges.

Through laser marking and engraving, wood can achieve high-precision patterns and text, while simultaneously supporting branding, personalized customization, and batch production. Whether it is a brand logo on furniture, commemorative patterns on craft gifts, or decorative patterns on wall panels, laser processing demonstrates unique value and broad application prospects.

Laser marking of wood

Characteristics of Wood and Processing Challenges

Wood, as a natural organic material, features distinctive textures and a porous structure, presenting specific challenges for laser processing. Firstly, wood is heat-sensitive, and excessive laser energy can cause surface charring, carbonization, or cracking, affecting appearance and product quality. Secondly, the hardness and density of wood vary depending on species, moisture content, and grain direction, leading to inconsistent processing results. Compared with metals or plastics, wood is inherently more difficult to work with.

Laser technology overcomes these difficulties through precise control of energy output and processing parameters. For example:

Pulsed laser beams prevent overheating, reducing the risk of charring and cracking.

Adjusting laser focus and scanning speed achieves delicate and clear engraving results.

Professional cooling and fume extraction systems maintain a clean working environment while enhancing surface smoothness and durability.

As a result, laser marking and engraving can achieve high-quality, high-precision processing on wood, opening broader creative and practical applications for furniture, crafts, and decorative industries.

Main Applications of Laser Marking and Engraving on Wood

Furniture Industry

In furniture manufacturing, laser marking and engraving can be used to apply brand logos, model numbers, and anti-counterfeiting serial numbers. It also enables the creation of intricate decorative patterns and artistic designs on furniture surfaces. Compared to traditional carving methods, laser processing offers higher precision and consistency, significantly enhancing both aesthetics and brand recognition.

Crafts and Gifts

Personalized wood crafts and gifts are increasingly in demand. Laser engraving allows names, blessings, or commemorative designs to be etched directly onto products, achieving customized effects. Combining laser technology with traditional woodworking preserves the unique charm of handcrafted items while imparting modern precision and added value.

Laser marking of wooden cups

Home Decoration and Architecture

In interior decoration and architectural applications, laser engraving can be applied to wall panels, flooring, and various decorative items. Laser processing enables complex geometric patterns or personalized designs, providing highly customizable elements to meet diverse spatial design requirements.

Packaging and Brand Promotion

Laser marking and engraving are also suitable for wooden packaging, such as gift boxes, wine boxes, and tea boxes. Fine laser markings enhance the packaging quality and strengthen brand promotion. Compared with printing methods, laser engraving is more durable and environmentally friendly, making it an essential tool for high-end packaging and brand communication.

Choosing the Right Laser Marking/Engraving Machine for Wood

Selecting the appropriate laser type is critical for wood processing, as the laser wavelength determines compatibility and directly affects results.

Fiber Laser Is Not Suitable for Wood

Fiber lasers typically operate at wavelengths around 1064 nm. While this short wavelength is effective for metals and high-reflectivity materials, it is poorly absorbed by wood. Wood’s uneven organic structure and varying density may lead to:

Uneven marking: Some areas cannot absorb enough energy, resulting in inconsistent engraving depth.

Charring: High localized energy causes carbonization or excessive burn marks.

Poor surface quality: Difficult to achieve clear, natural lines suitable for decorative or customized designs.

Therefore, fiber lasers are better suited for metals and plastics rather than wood.

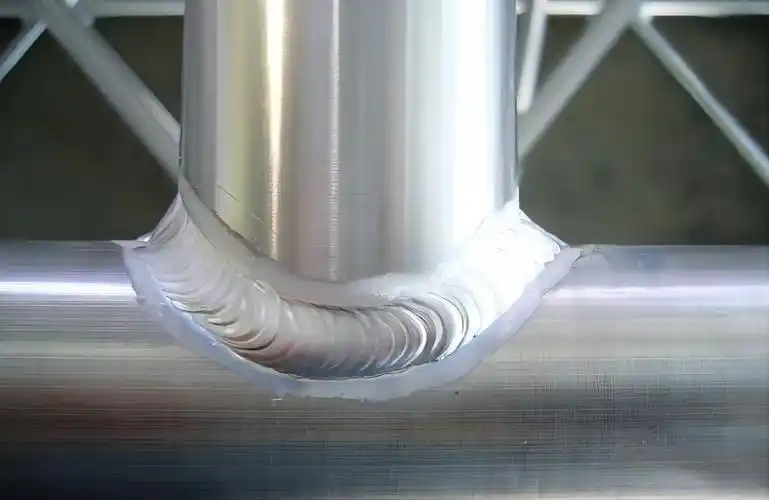

Recommended: CO₂ Laser Marking Machine

CO₂ lasers operate at 10.6 μm, a wavelength highly absorbed by wood, making them ideal for wood marking and engraving.

Advantages of ZS Laser’s CO₂ machines:

Wide material compatibility: Effective on hardwood, softwood, and composite woods for both engraving and cutting.

Natural engraving effects: Clear lines with strong contrast that highlight the wood grain, perfect for artistic patterns and brand logos.

Non-contact processing: Prevents chipping or cracking from physical tools, maintaining wood surface integrity.

Versatile applications: Suitable for shallow surface engraving or cutting, meeting the needs of furniture, crafts, decoration, and packaging.

CO2 Laser Marking Machine Multiple power options

Power Selection

In CO₂ lasers, power significantly affects engraving depth and efficiency:

Low power (30–60W): Ideal for shallow engraving, marking, and decorative designs.

Medium power (80–150W): Suitable for deeper engraving or small-scale cutting.

High power (150W+): Appropriate for thick wood cutting and large-scale production.

Users should choose power based on wood hardness and engraving depth requirements.

Software Compatibility

An efficient CO₂ laser marking/engraving machine should support vector graphics and complex designs and be compatible with mainstream design files (CorelDraw, AutoCAD, AI, etc.) to enable personalized customization and batch production. ZS Laser machines offer full compatibility.

Machine Performance

ZS Laser CO₂ machines feature:

Long lifespan: Laser tube life up to 8,000–10,000 hours.

High speed: Supports fast engraving for increased productivity.

Adjustable power: Flexible settings for shallow or deep engraving.

Easy maintenance: Options for air or water cooling; optimized optical components ensure stable long-term operation.

Contact Us for Professional Wood Laser Marking Solutions

Laser marking and engraving on wood provides high precision, non-contact processing, flexibility, and eco-friendliness, making it an ideal choice for furniture manufacturing, crafts, home decoration, and packaging. Compared to traditional methods, lasers deliver permanent, clear markings and allow intricate patterns and personalized designs, greatly enhancing aesthetics and added value.

With growing demand for customization and branding, wood laser processing offers vast application potential. Whether it is artistic engraving on furniture, personalized gifts, or decorative panels, laser technology provides stable, efficient, and sustainable solutions.

If you are looking for a suitable laser marking/engraving machine for wood, contact us today.

We offer:

Customized solutions: Recommend the best machine based on wood type, engraving depth, and production capacity.

Free sample testing: Experience the high-quality results of laser marking and engraving firsthand.

Professional technical support: Full guidance from selection and installation to after-sales service.

Upgrade your wood processing now and let laser technology add unique value to your products!

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.