In recent years, handheld laser welding machines have developed rapidly in the field of industrial manufacturing. With advantages such as flexibility, high efficiency, and aesthetically pleasing weld seams, they have become the preferred alternative to traditional welding methods for many factories. Whether it’s stainless steel, carbon steel, or aluminum, handheld laser welding machines can deliver excellent performance in most scenarios.

However, laser welding is not universal. While it can greatly reduce the skill barrier of welding and allow ordinary workers to operate after simple training, handheld equipment is not the best choice in certain special conditions. Blindly using it in such cases may result in poor welding quality, low efficiency, or even safety risks.

To help customers choose the right welding solution, ZS Laser has summarized five situations where handheld laser welding machines are not recommended, so you can avoid detours and unnecessary losses during equipment selection and application.

Handheld Laser Welding

1.Handheld laser welding is not recommended if the weld gap is too large.

When using a handheld laser welder, the weld gap is a key factor affecting weld quality. Because laser welding concentrates energy and creates a smaller molten pool, the weld alignment requirements are much higher than with traditional welding methods. So how do you determine if the gap is too large?

The reference standard is that the gap should not be larger than the wire diameter.

For example, if a 1.6mm wire is used, a good weld can be achieved with a weld gap less than 1.6mm. However, if the gap reaches 2.0mm or greater, it becomes difficult to ensure weld strength and weld quality. This is because when the gap is too large, the molten metal cannot effectively fill the gap, making defects such as cold welds, incomplete penetration, and porosity more likely to occur. Even adding wire to compensate or welding multiple times will reduce efficiency and affect the weld’s aesthetics and reliability.

2.Carefully select when weld special metals (such as titanium and copper).

Titanium and copper are highly reflective or possess unique physical properties, placing higher demands on laser beam and energy control, and the welding process is more complex. When welding these metals, a proofing test is essential. This test allows you to visually verify that the welding quality, weld formation, and strength meet your requirements.

Important reminder

If a manufacturer directly tells you, “These special metals are perfectly weldable,” be wary. Even if the supplier is confident, customers should not skip the proofing process, as each project’s working conditions vary, and material composition, thickness, and surface treatment can significantly impact welding results.

In contrast, for common metals like aluminum, stainless steel, and carbon steel, the process is relatively mature, and in most cases, handheld laser welding machines can be used with confidence without concern.

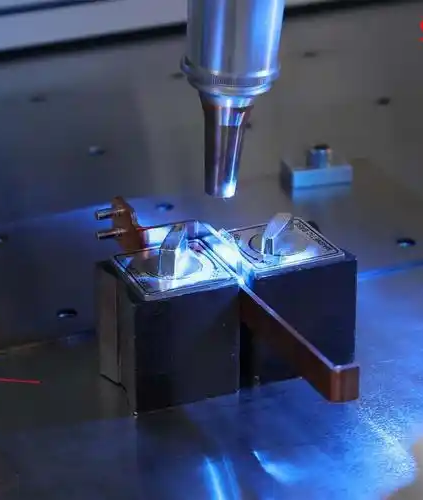

Laser welding copper

3.Handheld laser welding is not recommended for thick plates (>8mm).

When plate thickness exceeds 8mm, handheld laser welding machines are no longer the best choice.

The main reasons are:

High penetration and penetration requirements

Customers often have strict requirements for penetration, penetration, and weld width when welding thick plates. If the ideal penetration depth cannot be achieved in one go, weld reliability and strength cannot be guaranteed.

Low efficiency

While handheld laser welding is not completely ineffective for thick plates, it often requires multiple passes to meet the required weld quality. This significantly reduces efficiency and can easily lead to problems such as uneven welds and unstable weld formations. The greatest advantages of laser welding are high efficiency, speed, and aesthetically pleasing welds. However, in thick plate applications, these advantages are offset by the multiple passes required, making it less practical than traditional methods like submerged arc welding and gas shielded arc welding.

Therefore, if your needs focus on welding thick plates greater than 8mm, other traditional thick plate welding processes are more suitable, as they offer a better balance of efficiency and weld quality.

4.Workpieces requiring flaw detection or under pressure (such as pressure vessels)

In some industries and applications, welding quality requirements are far higher than in ordinary applications. For example, pressure vessels, pressure pipes, boilers, and gas tanks often withstand high pressure or long-term operating pressure. Any minor weld defect can pose a serious safety hazard.

Why is handheld laser welding unsuitable?

Manual operation is unstable.

While handheld laser welding does not necessarily result in defects, it does rely to a certain extent on the operator’s hand stability and experience, making it difficult to ensure that each weld is perfectly consistent in depth, width, and shape. Even experienced welders cannot avoid slight jitter or angle variations.

Lack of accuracy and consistency.

Pressure-bearing workpieces typically require nondestructive testing (NDT) such as ultrasonic testing and X-ray testing to ensure that the welds are free of pores, cracks, or inclusions. However, due to human interference, handheld welding often fails to meet NDT standards for weld consistency.

Lack of quality traceability.

In critical areas such as pressure vessels, welding processes require strict process documentation, parameter records, and traceability. Handheld devices, while flexible, make it difficult to fully record and reproduce process parameters, thus failing to meet industry standards.

A More Suitable Solution

For this type of work, the following is recommended:

Automated laser welding machines: These utilize robotic arms or CNC platforms to perform welding, offering controllable and repeatable parameters and meeting high consistency requirements.

Integrating with quality inspection processes: Automated equipment can integrate with inspection processes before and after welding to ensure weld traceability.

5. Handheld laser welding is not recommended for thin sheets (<0.4mm).

Although handheld laser welding offers the advantages of a small heat-affected zone and aesthetically pleasing welds, it presents significant challenges with ultra-thin sheets (less than 0.4mm).

Why is it unsuitable?

Easy to weld through

The laser’s high energy density can cause even the slightest deviation in the material’s thickness to burn through, rendering the workpiece scrapped.

Heat is difficult to control.

Thin sheets conduct heat quickly but have poor heat resistance. Even prolonged dwell time can cause localized overheating or deformation.

High scrap rate

Even with parameter adjustments, it’s difficult to completely avoid weld through or edge burns, significantly increasing scrap rates and costs in large-scale production.

Recommended solutions

For ultra-thin sheets, consider the following alternative processes:

Micro-arc welding and pulsed TIG welding → Easier to control heat input and avoid weld through.

Dedicated precision laser welding equipment → Lower power and finer control, suitable for ultra-thin materials. Handheld laser welders are highly effective in most metal welding scenarios, with only a few real limitations. Beyond the aforementioned scenarios, handheld laser welders can be used with confidence in most applications.

If you’re still unsure whether your workpiece is suitable for laser welding, ZS Laser offers free welding sample tests and professional process evaluations to help you confirm your results and ensure a secure and reliable investment.

Contact us today for a free sample test and make your welding more efficient and simpler!

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.