Ceramics are everywhere. From the bowls, cups, and tiles we use in daily life to the high-performance substrates, insulators, and medical components used in manufacturing, ceramics play an essential role. With their high hardness, heat resistance, and chemical stability, ceramics are widely applied across industries such as electronics, medical devices, automotive, aerospace, and home decoration.

Ceramic tea set laser marking samples

However, ceramics are challenging to mark. Traditional printing, painting, or labeling methods often fail because the marks fade, peel off, or wear away. When ceramic products are exposed to high temperatures, cleaning agents, or mechanical abrasion, these marks quickly disappear. This causes problems in both consumer and industrial contexts: for example, a logo on a coffee cup can vanish after repeated washing, or a serial number on a medical ceramic part may become unreadable.

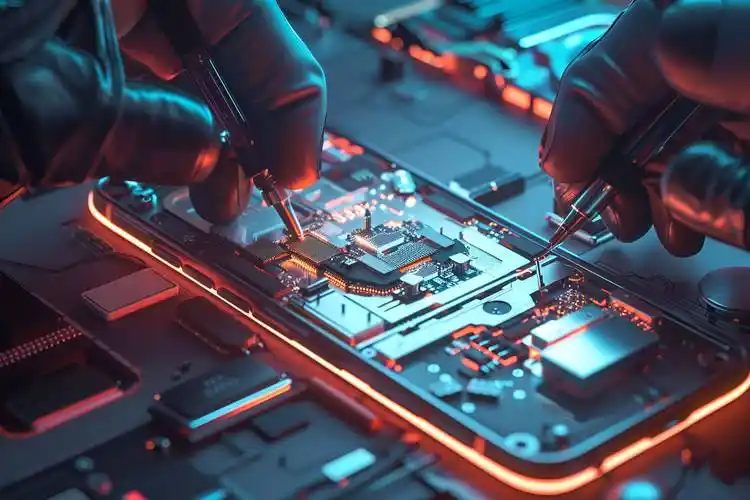

In this context, laser marking on ceramics becomes the ideal solution. Laser technology provides permanent, high-precision, non-contact marking without the need for consumables. Whether it is decorative patterns on porcelain cups or QR codes on alumina substrates, laser marking ensures clear and long-lasting results.

Types of Ceramics and Their Applications

Traditional Ceramics (Everyday Use)

Traditional ceramics are the items we are most familiar with, widely used in households, restaurants, and construction:

Tableware: Bowls, cups, mugs, plates, and teapots.

Tiles: Flooring tiles, wall tiles, and decorative tiles.

Decorative ceramics: Vases, ornaments, and personalized gifts.

Ceramic bowl laser marking sample

Laser marking applications for traditional ceramics:

Logos and branding: Cafés and restaurants engrave their logos on cups or plates to enhance brand visibility.

Personalization: Names, text, or artistic designs can be engraved on cups or tiles for gifts or decoration.

Functional markings: Engraving scales or permanent labels on ceramic containers or measuring cups.

Compared to printed patterns, laser-engraved marks are permanent, dishwasher-safe, non-polluting, and wear-resistant. On tiles, laser marking can also produce complex patterns or even QR codes.

Technical Ceramics (Industrial Use)

Technical ceramics, also known as advanced ceramics, are designed to meet performance requirements in demanding environments. Common types include:

Alumina (Al₂O₃) ceramics: Widely used in electronic substrates, insulating components, and cutting tools.

Zirconia (ZrO₂) ceramics: High strength and wear resistance, commonly used in dental implants, surgical instruments, and industrial parts.

Silicon nitride and silicon carbide ceramics: Used in aerospace, automotive, and energy applications for high-temperature and wear resistance.

Piezoelectric ceramics: Widely used in sensors, actuators, and medical devices.

Alumina ceramic marking sample

Laser marking applications for technical ceramics:

Electronics: Engraving QR codes, part numbers, and circuit markings on alumina substrates or semiconductor packages.

Medical industry: Engraving anti-counterfeit codes and batch numbers on zirconia implants or surgical tools for traceability.

Automotive and aerospace: Durable marking on high-temperature insulating components or safety parts to meet regulatory requirements.

In these scenarios, high precision and non-contact processing are crucial. Laser marking can achieve micron-level accuracy without applying mechanical stress, avoiding ceramic cracking.

Material Characteristics of Ceramics

To mark ceramics effectively, it is essential to understand their material properties:

Hardness and brittleness: Ceramics are extremely hard but brittle, making mechanical engraving difficult. High-energy lasers are ideal, but laser power and pulse parameters must be precisely controlled.

Surface properties: Ceramic surfaces are smooth, and laser absorption depends on color. White ceramics reflect more light and require higher energy, while darker ceramics absorb light better, allowing for slightly lower power.

Heat sensitivity: Local overheating can cause micro-cracks, so the heat-affected zone must be minimized during marking.

Key Laser Parameters and Settings

The appropriate laser parameters depend on the type of ceramic and application:

Power: Medium to low power is preferable to avoid overheating and cracking.

Pulse frequency: High frequency produces smoother surfaces, while low frequency can engrave deeper.

Scanning speed: Too fast results in shallow marks; too slow can cause burning.

Focus: Precise focusing ensures sharp edges and prevents energy dispersion.

Cooling: External cooling or segmented marking is recommended to reduce thermal stress.

Practical examples:

Alumina ceramics: CO₂ laser (20–40 W), scanning speed 200–500 mm/s, produces clear marks with minimal thermal impact.

Electronic ceramics: UV laser (3–10 W) is suitable for fine QR codes and micro-texts.

Glazed tableware or tiles: Fiber or CO₂ lasers can be used; slightly defocusing on glossy surfaces reduces the risk of cracks.

Practical Tips for Different Ceramic Applications

Everyday ceramics (cups, tiles, bowls):

Use moderate power to prevent glaze cracking.

Matte ceramics absorb laser energy better than glossy surfaces.

Always test on a sample before mass production.

Industrial ceramics (alumina, zirconia, etc.):

UV lasers are recommended for small, high-precision markings.

Avoid dwelling too long on one spot; distribute energy to prevent micro-cracks.

Laser marking on ceramics is a durable, precise, and flexible method. From personalized mugs and decorative tiles to medical implants, electronic substrates, and aerospace components, laser technology provides reliable solutions.

At ZS Laser, we combine years of industry experience with innovative engineering to offer the best ceramic laser marking solutions. We provide free sample testing, parameter recommendations, and CE-certified equipment that is easy to operate and durable, helping clients improve productivity.

Contact ZS Laser today to explore how our ceramic laser marking solutions can deliver long-lasting, precise, and efficient markings—whether for creative personalization or demanding industrial manufacturing.

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.