Prefabrication refers to the production method in which components or structural parts are manufactured in factories or workshops in advance and then transported to the site for rapid assembly. This approach effectively improves production efficiency, reduces construction difficulty, and ensures product quality consistency. The concept of prefabrication was first applied in the construction industry, such as precast concrete panels and modular buildings, and has gradually expanded to broader manufacturing fields, including metal processing.

Embedded parts welding in the construction industry

Metal Prefabrication refers to the process in which raw metal materials are processed into standardized or customized metal components in a factory through cutting, bending, welding, drilling, and other techniques, and then assembled on-site when needed. It is widely used in automotive manufacturing, aerospace, energy equipment, shipbuilding, and precision machinery. Compared to traditional on-site processing, metal prefabrication reduces errors, improves production efficiency, and is more suitable for large-scale, automated manufacturing.

As manufacturing evolves, companies demand higher standards for metal prefabrication: components must not only be durable but also exhibit high precision, consistency, and efficiency. Under this trend, traditional welding methods (such as MIG and TIG welding) increasingly reveal their limitations, while laser welding, with its high energy density, precise control, and automation compatibility, is becoming a key technology driving innovation in the metal prefabrication industry.

Advantages of Laser Welding in Metal Prefabrication

In the field of metal prefabrication, welding technology directly determines the quality, efficiency, and production cost of components. Compared with traditional welding methods, laser welding offers several unique advantages:

High Precision

The laser beam has extremely high directionality and energy concentration, allowing stable welding on complex shapes, small components, or parts requiring high precision. The welds are narrow and smooth, requiring minimal post-processing, making it ideal for precision prefabricated parts.

High Efficiency

Laser welding delivers energy at an extremely fast rate, achieving welding speeds several times higher than traditional methods. It can operate continuously and stably, supporting assembly-line production and greatly improving the efficiency of large-scale prefabrication.

Low Distortion

Due to the minimal heat-affected zone, laser welding limits the thermal impact on components, effectively reducing residual stress and post-weld deformation. This is crucial for prefabricated metal parts with strict dimensional accuracy requirements.

Automation Compatibility

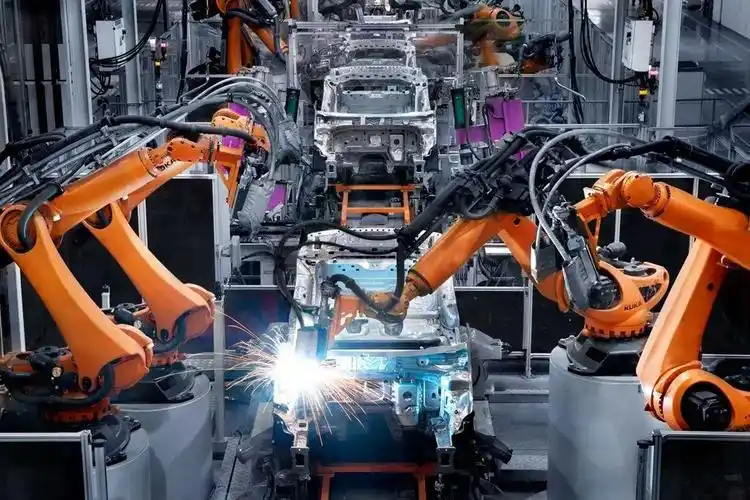

Laser welding can be easily integrated with robots, CNC systems, and smart manufacturing platforms to achieve fully automated welding processes. This not only enhances production consistency and reliability but also aligns with the trend of intelligent and unmanned metal prefabrication.

Multi-Material Adaptability

Laser welding can handle metals of different thicknesses and types, including certain dissimilar metal combinations that are difficult to weld with traditional methods. This flexibility makes it invaluable in diversified prefabrication production.

Laser welding of prefabrication parts

Typical Applications of Laser Welding in Metal Prefabrication

Laser welding is not just an upgrade in welding methods; it is an important technology supporting industrial transformation. By providing high precision, high speed, and controllable energy input, laser welding enables the efficient factory production of prefabricated components, which can then be transported to construction sites or assembly lines, significantly improving production efficiency and product consistency. Typical applications include:

Automotive Manufacturing

In the automotive industry, prefabricated metal components are mass-produced in factories and then integrated into vehicle assembly lines. Common applications of laser welding include:

Body structural components: Doors, roofs, and frames made of steel or aluminum. Laser welding provides deep, continuous, and uniform welds, ensuring structural strength and lightweight design.

Battery modules and housings: For electric vehicles, weld quality is critical for safety. Laser welding ensures highly sealed joints, preventing electrolyte leakage while avoiding excessive heat that could damage battery performance.

Exhaust and drivetrain components: These require high heat and corrosion resistance; laser welding reduces defects and extends service life.

By applying laser welding in automotive manufacturing, welding efficiency is improved while meeting the industry’s dual demands for lightweight and high-strength components.

Aerospace

In aerospace, prefabricated components are processed in ground factories and then transported to assembly sites or launch centers. Applications include:

Lightweight alloy parts: Such as aircraft skins and wing frames, typically made from aluminum or titanium alloys. Traditional welding can cause thermal cracking, while laser welding achieves strong joints without compromising material performance.

High-strength structural components: Engine parts, fuel tanks, and other critical components. Laser welding provides deep penetration, ensuring reliability under high temperature and pressure.

Sealed components: Satellite casings and rocket fuel lines require vacuum-tight welds with long service life. Laser welding ensures these standards.

Laser welding in aerospace helps achieve weight reduction, strength retention, and high reliability, making it a key prefabrication technology.

Energy Equipment

Energy equipment often involves large and complex structures, with many components prefabricated in factories before site installation. Applications include:

Pressure vessels and pipelines: Used in oil, chemical, and gas transportation. Laser welding provides uniform welds to prevent leakage and ensure safe operation.

Wind power equipment: Such as wind turbine shafts and flange connections, laser welding enables efficient joining of large-diameter steel components.

Nuclear components: Fuel cladding and heat exchanger tubes require laser welding to ensure reliability under extreme conditions.

Laser welding enhances the prefabrication efficiency, durability, and safety of energy equipment.

Pipe prefabrication welding

Construction and Steel Structures

Modern construction increasingly uses prefabricated steel components assembled quickly on-site. Laser welding contributes significantly:

Prefabricated steel beams and plates: Enables fast, uniform welds in factory settings, reducing post-processing.

Modular building units: Steel structural panels and roof beams benefit from laser welding’s high efficiency, shortening production cycles.

Bridge steel structures: Large-span bridges require many prefabricated parts; laser welding ensures strength and durability, reducing maintenance costs.

In construction, laser welding supports rapid assembly and industrialized construction, improving project efficiency and quality.

Precision Manufacturing

Prefabricated parts in precision manufacturing are often small and highly accurate. Applications include:

Electronic components: Sensor packages, metal pins in microcircuits, welded with micron-level precision.

Medical devices: Stainless steel needles, implants, surgical instruments; laser welding ensures smooth, contamination-free joints meeting medical standards.

Precision instruments: Optical and measurement device components; laser welding ensures high assembly accuracy and stability.

In precision manufacturing, laser welding has become indispensable due to its non-contact operation, high accuracy, and cleanliness.

Technical Challenges and Solutions

Although laser welding offers significant advantages in metal prefabrication, practical applications face several challenges. Based on ZS Laser’s experience in upgrading welding systems for numerous domestic and international clients, key solutions include:

High Reflectivity of Metals

Many metals (e.g., aluminum, copper, silver) have high reflectivity, reducing laser energy absorption and affecting welding efficiency and quality.

Solutions:

Use high-power fiber lasers to provide sufficient energy and overcome high reflectivity.

Surface pre-treatment, such as sandblasting or black oxide coating, to enhance laser absorption.

Optimize laser parameters (wavelength, focal length, pulse mode) for stronger penetration and concentrated energy.

High Assembly Precision Requirements

Laser welding’s narrow welds and small heat-affected zones demand precise component alignment. Misalignment can lead to discontinuous welds or insufficient fusion.

Solutions:

Automated fixtures and positioning systems (CNC clamps, vacuum adsorption, or mechanical positioning devices).

Real-time visual inspection with laser displacement sensors, CCD cameras, or 3D vision systems for closed-loop control.

Robotic welding integration for precise motion control, reducing human error and improving consistency.

Welding of Uneven Thickness Components

Prefabricated parts often have varying thickness or complex geometries. Single welding modes may cause burn-through or shallow penetration.

Solutions:

Multi-mode welding: Combine conduction mode and keyhole mode welding to adapt power based on material thickness.

Oscillating welding: Minor lateral movement of the laser head along the weld seam increases molten pool width and uniformity, accommodating thickness variations.

Future Development Trends

As metal prefabrication advances, laser welding technology continues to evolve with promising trends:

Integration with Smart Manufacturing and Industry 4.0

Laser welding equipment is increasingly connected to intelligent manufacturing systems, achieving highly automated and digital production:

AI quality monitoring: Real-time analysis of weld images and temperature data to detect defects such as porosity, cracks, or lack of fusion.

Digital twin technology: Simulate welding processes virtually, optimize parameters and paths, reduce trial-and-error costs, and increase efficiency.

Remote monitoring and data tracking: Factory managers can access real-time equipment status, production progress, and quality reports, enabling full-process digital management.

Broader Material Compatibility

Laser welding will extend beyond uniform materials and thickness:

Dissimilar metal welding: Aluminum-steel, copper-aluminum combinations for lightweight and multifunctional assemblies.

Ultra-thin and thick materials: Multi-mode or hybrid welding covers components from tiny electronics to thick structural parts.

High-performance alloys: Meeting aerospace and nuclear industry requirements for strength and corrosion resistance.

High-Power and Ultrafast Laser Applications

High-power lasers: For thick structural components, large prefabricated parts, and industrial manufacturing in automotive and shipbuilding, improving penetration and speed.

Ultrafast lasers (femtosecond/picosecond): Enable low-heat-impact welding, suitable for precision electronics and medical devices, minimizing deformation and residual stress.

Laser welding is becoming an indispensable core technology in metal prefabrication, ensuring high precision, efficiency, and automation.

If you are seeking high-performance laser welding equipment or wish to upgrade your welding production line, ZS Laser, with over a decade of industry experience, provides customized solutions, free sample welding tests, and CE-certified machines.

Contact us today to let our professional team deliver efficient, safe, and innovative laser welding solutions for your metal prefabrication projects!

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.