Laser welding has become one of the most advanced joining technologies in modern manufacturing. It offers high precision, minimal deformation, and high production efficiency, making it widely used in industries such as automotive, aerospace, electronics, and construction. However, not all metals behave equally under a laser beam. Some materials are well-suited for laser welding, while others require additional protective measures or are simply not recommended.

ZS Laser has been deeply involved in laser welding equipment for over a decade. Below are some of our experiences, which can help you determine if a laser welding machine is suitable for your production.

Stainless Steel Laser Welding

Suitable Materials for Laser Welding

Stainless Steel (Thickness Up to 8mm)

Stainless steel is one of the most suitable materials for laser welding. It has excellent laser energy absorption, resulting in stable welds and minimal spatter. It is widely used in kitchenware, furniture, medical equipment, and industrial components.

The recommended welding thickness for stainless steel is 8mm or less.

Carbon Steel (Thickness Up to 8mm)

Carbon steel, like stainless steel, is also well-suited for laser welding. The weld seam is smooth, mechanically strong, and easy to process, making it suitable for sheet metal, mechanical parts, and construction applications.

For carbon steel, a thickness of 8mm or less is recommended for stable welding.

Cold-dip galvanized steel

Cold-dip galvanized steel may produce some spatter during laser welding, but the overall weld quality is excellent, so it can also be laser welded with relatively good results. Cold-dip galvanized steel welding is commonly used for frames, housings, and protective structures. Proper lens protection and correct welding parameters are recommended during welding.

The above three materials can be laser welded without requiring many precautions. The following materials require some precautions.

Materials Requiring Attention

Aluminum and aluminum alloys

Aluminum is highly reflective, making laser welding more challenging. Improper welding can result in energy reflection, unstable penetration, and weld porosity. Therefore, when welding aluminum and aluminum alloys, higher you should use higher laser power or oscillating welding and shielding gas to achieve better welding results. Preheat treatment may also be required in some special cases.

Welding aluminum and aluminum alloys is commonly used in automotive, aerospace, and lightweight structural components.

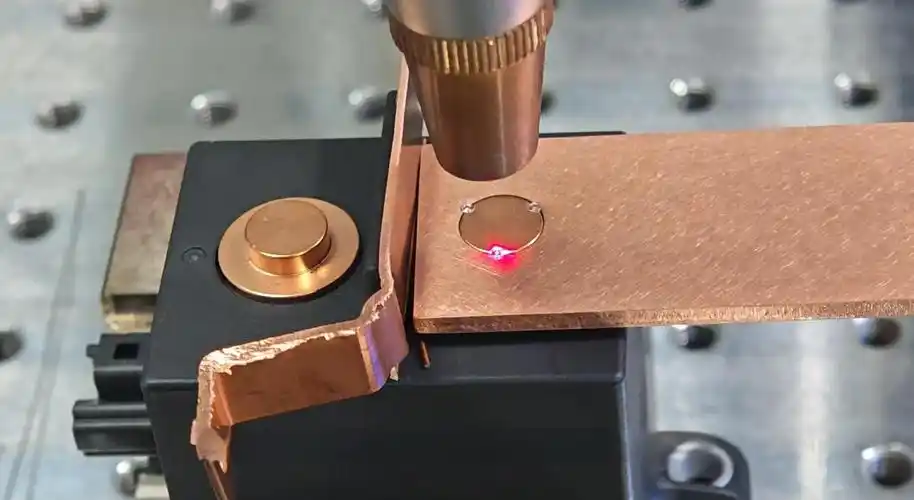

Copper, brass, and copper

Copper and copper alloys are also highly reflective materials. Laser welding can also present problems such as energy absorption difficulties and unstable weld quality. However, these issues can be effectively avoided by properly adjusting laser parameters and selecting an appropriate laser source.

If you are welding these materials, we recommend conducting a free sample welding test before mass production. Once the test is complete, proceed with mass production. Copper is commonly used for electrical contacts, connectors, and precision components.

Laser welding copper

The materials listed above can be perfectly welded with laser welding with some adjustments. The following materials are not recommended for laser welding.

Materials Not Recommended for Laser Welding

Hot-dip galvanized steel

Hot-dip galvanized steel welding produces excessive spatter, which can damage protective lenses and optical components. The resulting weld may be weak and unsightly. Therefore, we do not recommend laser welding this material.

For hot-dip galvanized steel, ZS Laser recommends removing the galvanizing layer before welding or using other welding techniques.

Laser welding is a powerful technology, but it is not suitable for all materials. If you are unsure whether your material is suitable for laser welding, please contact us for free sample testing and expert consultation. Our engineers will recommend the best solution based on your product and production needs.

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.