In the field of metal welding, aluminum has long been considered one of the most difficult materials to weld. Even with laser welders, some users encounter problems such as unstable welds, wire blockage, and porosity. Why is this?

The reason is simple: aluminum’s physical properties—its softness, high reflectivity, and strong thermal conductivity—require careful attention to detail during the welding process. If these details are overlooked, even the most advanced laser welder can fail.

ZS Laser has summarized customer problems and will explain four key details. Mastering these four aspects can save you from significant trouble.

Tip 1: Choosing the Right Aluminum Welding Wire Diameter

Many users overlook the importance of wire diameter after selecting a laser welder. Aluminum wire is softer than steel wire. If the diameter is too thin, it can easily bend or become stuck in the wire feeder.

ZS Laser recommends using 1.2mm or 1.6mm aluminum wire.

0.8mm or 1.0mm wire is not recommended because they are too thin and can easily cause wire blockage.

Recommended grade: 5356 aluminum wire. This grade is relatively harder, provides more stable wire feeding, and is more suitable for use with laser welding machines.

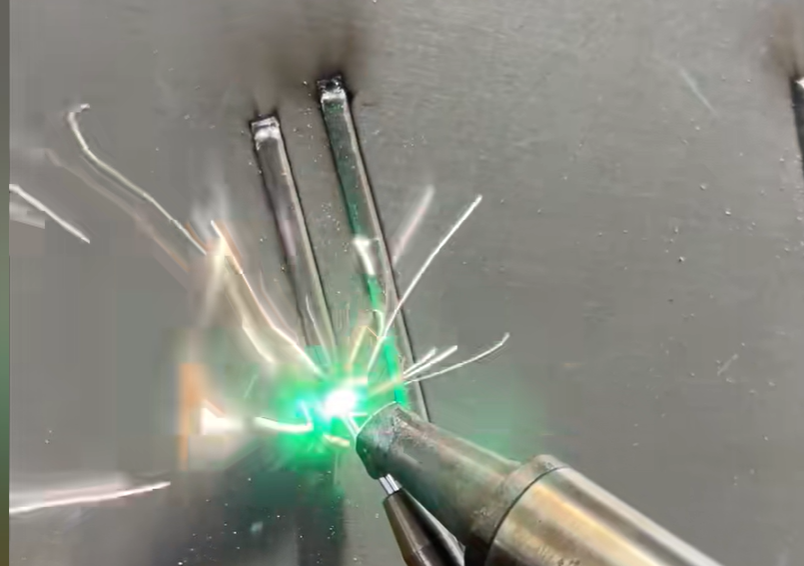

Correct focal length weld display

Tip 2: Use the Correct Wire Feed Roller (U-Groove)

The wire feed roll may seem insignificant, but it plays a crucial role in welding stability. When welding aluminum, choose a wire feed roll specifically designed for aluminum. Common types include the following:

V-Groove Wire Feed Roller: Suitable for carbon steel and stainless steel. However, it can easily deform aluminum wire, causing wire jams.

U-Groove Wire Feed Roller: Designed specifically for aluminum wire, with a smooth inner groove that prevents the wire from being squeezed during feeding, resulting in smoother wire feeding.

When choosing a wire feed roll, pay attention to the model number. Rollers with a “U” in the model number, such as 1.2U or 1.6U, are suitable, while rolls with a “V” in the model number, such as 1.6V, are not suitable for aluminum welding.

V-Groove Wire Feed Roller And U-Groove Wire Feed Roller

Tip 3: Choose the right wire feed roller (graphite).

Aluminum wire is very soft, and improper wire feed roller selection can easily cause problems.

Spring wire feed liners: The spring wire feeding line is relatively hard, and the aluminum wire rubs against the spring during the wire feeding process.Over time, they can easily wear the aluminum wire, causing chipping and clogging, resulting in discontinuous welds.

Graphite wire feed liners: Their smooth, soft surface prevents scratching the aluminum wire, ensuring smooth wire feed and consistent, stable welding.

For this reason, graphite wire feed liners are essential for optimal performance.

Don’t Use Spring wire feed liners

Tip 4: Adjust the laser focal length

Focus is a detail many beginners often overlook.

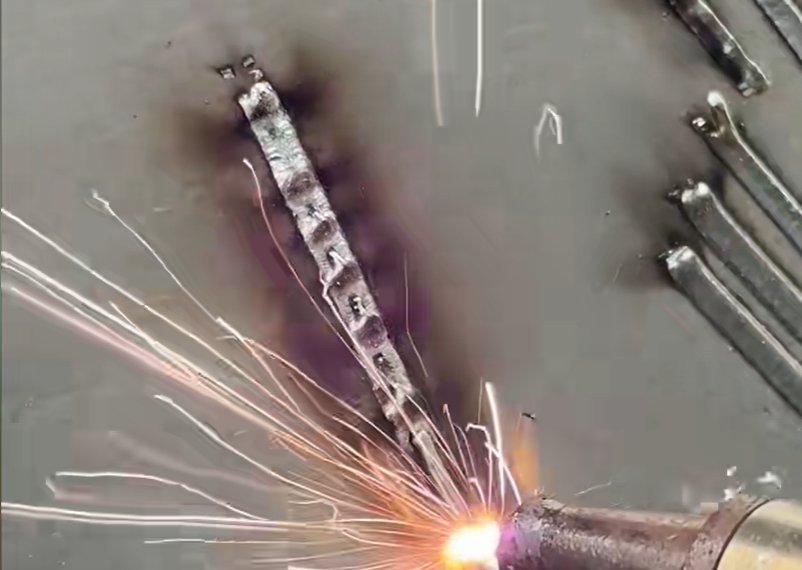

Inaccurate focal length: The laser energy cannot be properly focused at the weld point, resulting in an unstable weld pool, uneven welds, or even no penetration.

Focus inaccurate weld display

Accurate focal length: Concentrated energy results in smooth welds and consistent weld depth, significantly improving overall aesthetics and strength.

It is recommended to adjust the focus on scrap material before welding to ensure accurate focal length before proceeding.

The reason aluminum laser welding is often considered difficult is often due to a lack of mastery of the details. By mastering the four key points mentioned above, even beginners can quickly improve welding stability and achieve beautiful, strong welds.

If you’re facing challenges welding aluminum, ZS Laser offers a complete solution. We offer free welding sample testing: Send us your workpiece and we’ll test and recommend optimal parameters. We also offer one-stop equipment support: From handheld to automated models, we can meet diverse application needs.

Contact us today to get a laser welding solution tailored to your needs.

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.