In recent years, the laser tube cutting machine market has become more mature and competitive than ever.Whether you run a small sheet metal workshop or a large metal fabrication plant, everyone is looking for higher precision, better efficiency, and smarter automation.However, with more suppliers entering the market, many customers find it increasingly difficult to determine which machine is truly reliable and suitable for their needs.Machines may look similar from the outside, but their performance can vary greatly — often due to differences in design details, configuration quality, and software systems.

This article will help you understand how to choose a high-performance, reliable laser tube cutting machine and make the right investment decision.

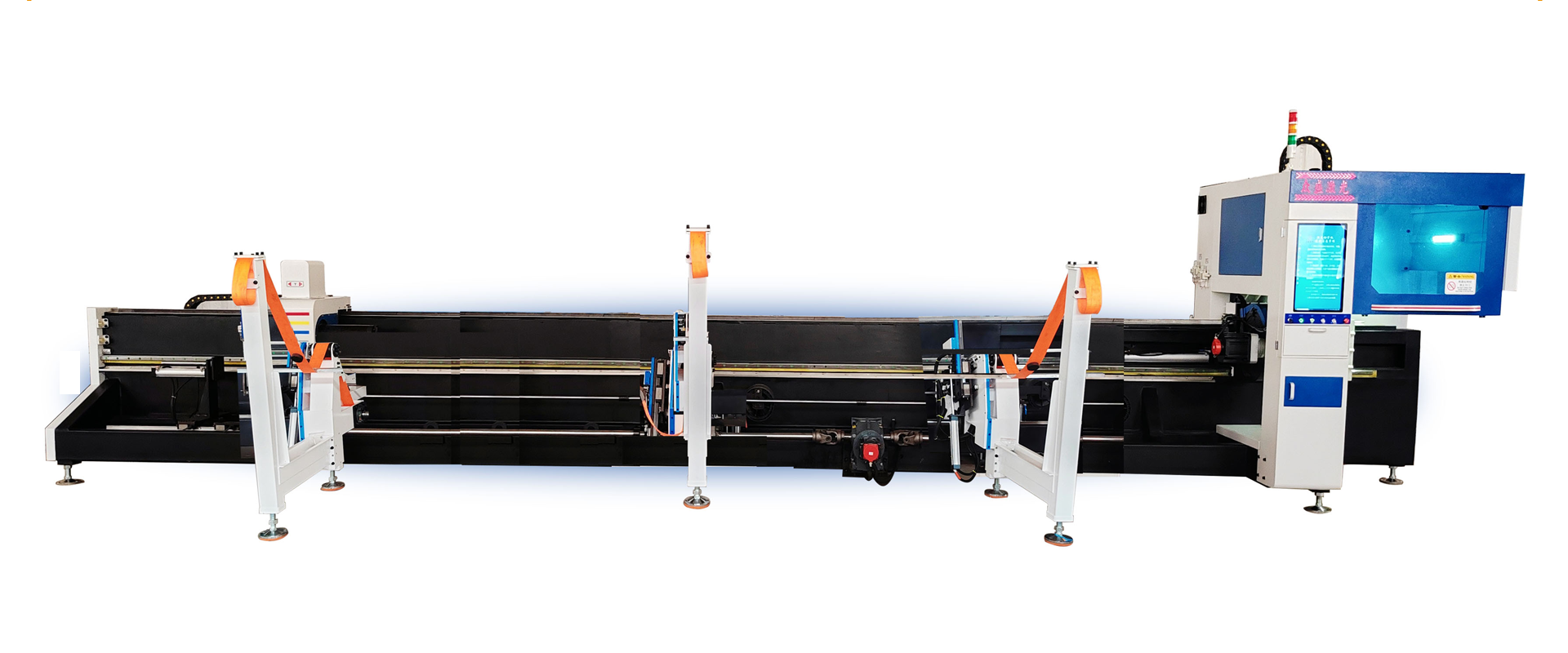

CNC Laser Tube Cutting Machine

Choose Based on Application Scope

What materials can a laser tube cutting machine process?

Laser tube cutting machines are mainly used for metal tube cutting, including carbon steel, stainless steel, aluminum alloy, copper, and other metal alloys.They are not suitable for non-metallic materials such as PVC or plastic tubes. Therefore, if your materials are non-metal, we do not recommend this type of machine.

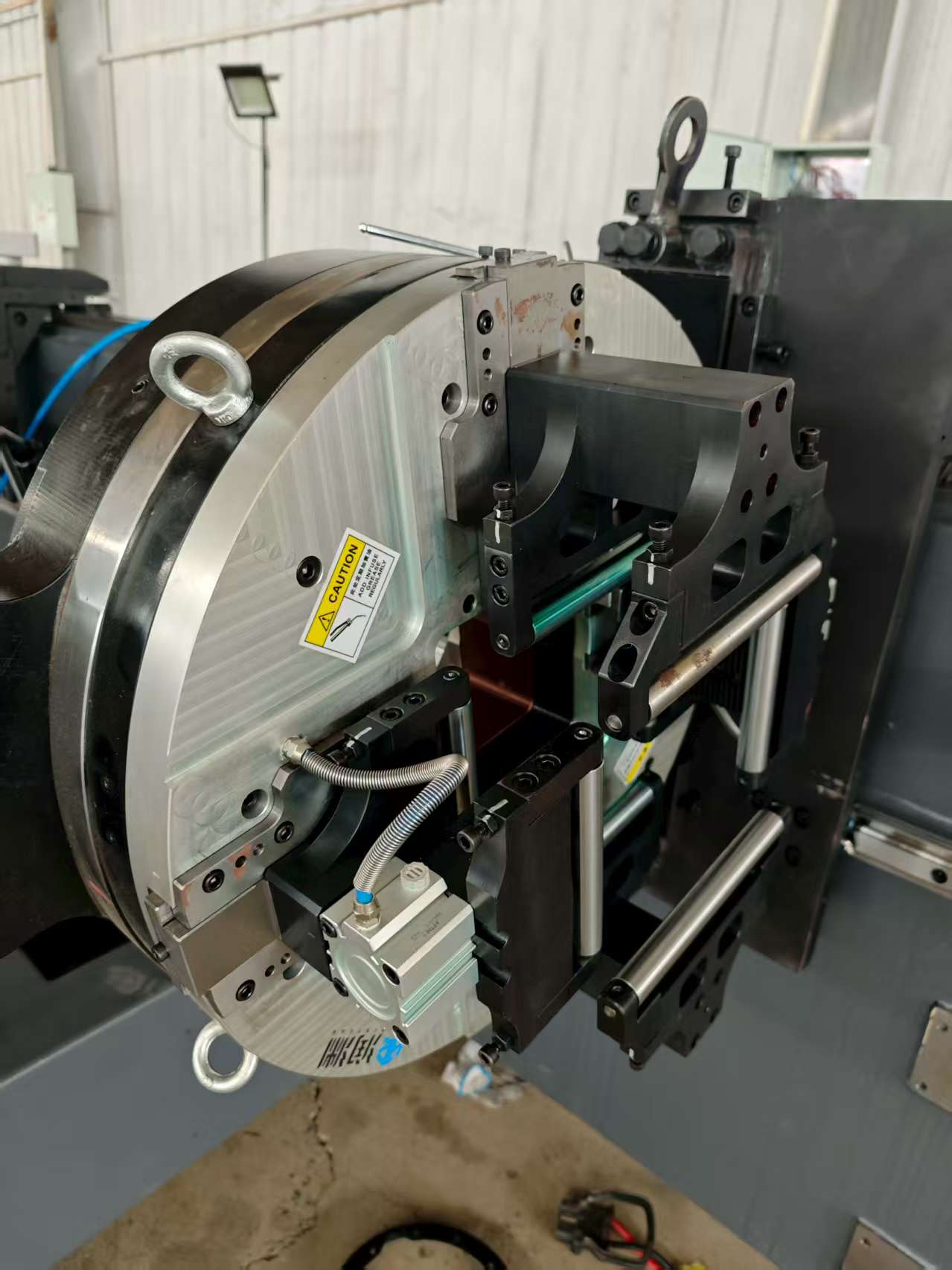

In terms of tube shapes, most machines on the market can easily cut round, square, and rectangular tubes — these are considered standard capabilities.However, if you need to cut special-shaped tubes such as oval, triangular, or custom profiles, you must confirm whether the chuck clamping system supports customization.Some manufacturers can design custom fixtures to ensure cutting stability for special tubes. Whether or not the supplier supports customization is also an important indicator of their professionalism and reliability.

Choosing the Right Chuck System

Chuck Size

The chuck size should match the outer diameter of your tubes.

Common options include 120mm, 170mm, and 240mm, which refer to the maximum cutting diameter.For example, if your largest tube diameter is around 150mm, a 170mm chuck would be suitable.We use full-stroke chucks, capable of flexibly clamping tubes from 20mm up to the maximum diameter without changing jaws.

Chuck Type

Chucks can be classified as full-stroke or half-stroke.

Full-stroke chucks allow adjustment across the full range (20mm to maximum diameter).Half-stroke chucks can only be adjusted in sections.

In addition, there are standard chucks and precision chucks:

Standard chucks are practical and economical for general use.Precision chucks feature a maintenance-free design, require no cleaning, and offer higher accuracy — ideal for demanding applications.We recommend choosing precision chucks, as they reduce maintenance effort and potential issues during long-term use.

Number of Chucks

A dual-chuck system is sufficient for most cutting needs and allows zero-tailing cutting through front-chuck movement, minimizing material waste.For extra-long or heavy tubes, a three-chuck or four-chuck configuration may be used to enhance stability.

Selecting the Right Loading System

Depending on your production scale, you can choose from manual, semi-automatic, or fully automatic loading systems:

Fully automatic:Ideal for large-batch, continuous production.

Semi-automatic:Suitable for small- to medium-batch or mixed-size production.

Manual loading:Not recommended, as it lowers efficiency and increases labor costs.

High-quality loading systems are often equipped with pre-loading functions, which prepare the next tube while the current one is being processed — significantly reducing idle time.

If your tube sizes vary widely and batches are small, semi-automatic loading may be sufficient.However, in general, the higher the automation level, the better the efficiency and consistency.

In special cases,for example, if you frequently switch between different tube diameters — manual loading may still be considered.

Machine Design and Adjustability

If you often cut tubes of different diameters, switching speed is crucial.Machines with quick-adjustment mechanisms can greatly save setup time.

For example, our machines use manually adjustable support brackets, which are easy to operate and much faster than traditional adjustment methods.This design is especially useful for factories that produce a wide variety of parts.

Choosing the Right Nesting Software

Many buyers focus only on the hardware while ignoring the importance of nesting software — yet it directly affects material utilization and cutting efficiency.Currently, no laser tube cutting machine can automatically perform multi-part nesting on its own.Therefore, if you process multiple tube types or materials (such as angle steel, channel steel, or H-beams), a good nesting software is essential for quick part switching and multi-function cutting.It helps optimize layouts, reduce material waste, and improve productivity.

Laser tube cutting machine details

Selecting the Laser Source and Cutting Head

Laser Source

The laser source is the heart of the machine.

We recommend choosing top-tier brands such as Raycus or MAX Photonics.

For most metal tube applications, a power rating of 2000W or higher is recommended.

Choose the right power level based on tube thickness to balance cutting speed, stability, and cost.

Cutting Head

For thin-walled or sharp-angled profiles (e.g., H-beams, special-shaped tubes), use a narrow-tip cutting head.Its smaller nozzle and sensor reduce the risk of collision during cutting complex shapes.This type of head performs safely and stably for curved or irregular geometries, though it may offer slightly lower surface smoothness on straight cuts.

Control System:The Brain of the Machine

The control system determines the reliability and ease of use of the equipment.Among domestic systems, Bochu (Friendess) is widely recognized as the most stable and mature solution.A robust control system reduces software failures, minimizes downtime, and ensures consistent, high-precision operation.

How to Evaluate a Reliable Supplier

Before purchasing, confirm whether the supplier can provide:

Free sample cutting tests to verify actual performance;

Customized fixtures and loading solutions for special tubes;

Comprehensive after-sales and training support, including software operation and spare parts service.

A trustworthy manufacturer focuses on long-term production efficiency, not just offering the lowest price.

As laser tube cutting technology becomes the industry standard in modern metal fabrication, choosing the right machine is more important — and more challenging — than ever.A truly outstanding laser tube cutting machine depends on the right combination of chuck system, automation level, nesting software, laser source, and control system.These factors directly determine your cutting accuracy, production efficiency, and long-term maintenance cost.

If you’re still unsure which configuration best fits your production needs, our engineering team can provide professional consultation and free sample testing.

Contact us today to test your materials and see how laser tube cutting can enhance your production efficiency and reduce costs.

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.