An industrial laser welding machine is a high-precision system that uses a concentrated laser beam to join metal parts. Unlike traditional welding methods that rely on an electric arc or filler materials, laser welding delivers energy directly to the joint, resulting in a clean, strong, and consistent weld.

In today’s competitive and efficiency-driven manufacturing landscape, the importance of industrial laser welding machines is growing. From the automotive and aerospace industries to electronics and medical devices, various sectors are increasingly adopting laser welding due to its higher speed and precision, as well as the lower skill requirements for welders. These factors significantly reduce operational costs for businesses.

Below, ZS Laser will guide you through everything you need to know about industrial laser welding machines: what makes these machines unique, their key advantages, the industries they excel in, and how to choose the right system for your business. Whether you are new to laser welding or considering an upgrade to your existing equipment, you’ll find the right advice here to help you make a decision.

Industrial Laser Welding

What Is an Industrial Laser Welding Machine?

An industrial laser welding machine is a welding system dedicated to a variety of industrial applications. It focuses a high-energy laser beam onto the material’s surface to generate intense heat, creating a small molten pool that fuses the parts together. Because the process is highly localized, it can achieve deep penetration welds while minimizing the heat-affected zone (HAZ), which reduces deformation and preserves the mechanical properties of the surrounding material.

Compared to traditional welding methods like TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), or spot welding, laser welding offers several significant advantages:

Higher Precision – TIG and MIG welding often create wider seams and larger HAZs, whereas laser welding can achieve micron-level precision, resulting in narrower cuts and less material deformation.

Deeper Penetration – A focused laser can achieve strong welds at a considerable depth, which is difficult to replicate with traditional processes.

Faster Speed – Laser welding is ideal for high-volume production lines, with efficiency far surpassing spot welding and manual processes.

Automation Integration – Unlike manual TIG or MIG welding, laser welding can be seamlessly integrated with automated systems, ensuring consistent and repeatable weld results.

Industrial Laser Welding Machine

Applications of Industrial Laser Welding Machines

One of the greatest advantages of industrial laser welding machines is their wide range of applications. This technology is used across industries that demand high precision, durability, and efficiency. Here are some of the most common industrial applications of laser welding machines and the types of parts they typically handle:

Automotive Industry

Laser welding is widely used in automotive manufacturing to produce lightweight yet strong components. Typical applications include welding electric vehicle battery packs, body structures, exhaust systems, transmission components, and fuel injectors. Its high speed and precision make it ideal for mass production with consistent weld quality.

Aerospace

Aircraft require high-strength, lightweight joints that can withstand extreme conditions. Laser welding is applied to weld titanium alloy turbine blades, aluminum fuselage panels, fuel tanks, and engine components to ensure strength and minimal deformation.

Electronics & Electrical Engineering

Miniature electronic and electrical components require extremely precise welding. High-precision laser welding is used for micro-connectors, sensors, PCB assemblies, lithium battery casings, and shielded enclosures. The narrow seam and low heat input prevent damage to sensitive electronic parts.

Medical Devices

In the medical field, hygiene and durability are critical, and laser welding can create smooth, contamination-free joints. It is often used for tasks like welding surgical instruments, stainless steel implants, endoscopic tools, pacemaker casings, and dental equipment.

Energy & Industrial Equipment

Laser welding supports industries like power generation and heavy machinery. Applications include welding components for oil and gas pipelines, pressure vessels, turbine assemblies, hydraulic systems, and industrial gears—industries that require long-lasting welds.

Jewelry & Luxury Goods

Jewelry and luxury goods demand both aesthetics and precision. Laser welding is used for repairing gold and silver jewelry, watch components, and decorative metal parts, providing seamless connections with no visible marks.

Everyday Household Items

For everyday items, laser welding provides both strength and aesthetics. It can be used for welding stainless steel kitchenware, phone frames, laptop casings, and headphone components.

Besides these, any welding scenario you can think of—like welding door handles, window components, or bicycle frames—can use a laser welding machine. Laser welding produces strong, clean, and precise welds, making it a key driver of innovation in manufacturing.

Types of Industrial Laser Welding Machines

There are various types of industrial laser welding machines based on different classification criteria. Below, we’ll briefly classify them by application, power level, and laser mode.

By Application and Automation Level

Handheld Industrial Laser Welding Machines

Welding is performed with a handheld welding gun, and the machine chassis is flexible and can be easily moved. Their flexible design makes them suitable for welding metal furniture, kitchenware, small automotive parts, and custom metal parts. They can also be used for repairing large, immobile workpieces.

Advantages: Easy to operate, simple to set up, portable, and affordable, making them suitable for small and medium-sized enterprises that need versatility.

handled laser welding machine

Semi-Automatic Laser Welding Systems

Designed for medium-volume production, these systems are semi-automated, requiring the operator to make simple position adjustments. They often come with an assisted arm for easy adjustment and are commonly used in electronics, appliance components, and precision sheet metal fabrication.

Advantages: Balances cost and productivity, reduces manual labor intensity, and improves both weld quality and work efficiency.

Fully Automatic Platform Welding Systems

Controlled by CNC, these systems are equipped with a welding platform and can be customized with jigs and fixtures. Once the program is input, the welding task proceeds automatically. They are designed for high-volume production, such as for mass-producing automotive accessories, door and window fittings, or pipe fittings that are of the same specifications.

Advantages: Provides the highest efficiency; the operator only needs to place the product, and the welding program starts automatically. No manual adjustment is needed during the entire process, ensuring consistent weld quality.

Fully Automatic Robotic Welding Systems

These are robotic welding arms that can be integrated into a production line. The robot arm welds automatically, making it suitable for batch welding of large workpieces without human intervention. They are commonly used for welding car bodies, engines, and chassis on automotive production lines, as well as large aerospace components.

Advantages: Seamlessly integrates into production lines for mass production, operates 24/7, offers high efficiency, and provides consistent weld quality.

By Power Level

Low-Power Laser Welding Machines (≤1000W)

Suitable for thin metals, microelectronics, jewelry, and precision medical devices. They produce fine welds with minimal heat impact.

Medium-Power Laser Welding Machines (1500W)

A popular choice for general manufacturing, automotive parts, furniture, and consumer goods. They strike a balance between cost, speed, and material compatibility.

High-Power Laser Welding Machines (3000W)

Used for thick metal sheets, heavy machinery, pipes, and aerospace components. They can ensure deep penetration welds and strong structural seams.

By Laser Output Mode

Continuous Wave (CW) Laser Welding Machines

Provide a constant, steady beam for deep penetration welding. Commonly used for car frames, pipes, and heavy machinery.

Advantages: Fast and efficient, ideal for long welds.

Pulsed Laser Welding Machines

Emit laser energy in controlled, short pulses, making them perfect for thin sheets, microelectronics, and precision medical devices.

Advantages: Minimal heat input, reducing the risk of thermal deformation and suitable for spot welding of precision components.

The types of industrial laser welding machines can be classified based on their level of automation (handheld, semi-automatic, fully automatic, or robotic laser welding solutions), power range, and laser mode. Each type is optimized for specific applications, ensuring manufacturers can find the perfect balance of precision, speed, and cost-effectiveness.

How to Choose the Right Industrial Laser Welding Machine

Choosing an industrial laser welding machine is not a one-size-fits-all decision. The right system depends on your material requirements, production scale, automation needs, and budget. Here are the key factors to consider when selecting the best industrial laser welding machine for your business:

Material Type and Thickness Different materials react differently to laser welding:

Stainless Steel: Excellent weldability, widely used in the automotive, furniture, and medical industries.

Aluminum Alloys: Requires higher precision and sometimes pulsed laser welding to control heat input.

Carbon Steel: High strength and cost-effective, suitable for structural parts and industrial equipment. Select the power and laser type based on the material thickness, from thin sheets of 0.5 mm to thick plates over 10 mm.

Production Scale

Small Batches/Prototyping: Handheld or semi-automatic machines offer flexibility and quick setup.

Mass Production: Automated or robotic systems ensure consistency, repeatability, and 24/7 operation.

Power Requirements

1000W: Suitable for thin sheets, electronics, and light manufacturing.

1500W: A balanced choice for small and medium-sized businesses with a wide range of applications.

3000W: For thicker materials, structural welding, and high-strength components.

Automation Needs

Handheld: Flexible, cost-effective, and easy to operate.

Semi-Automatic: Stable welding with moderate automation.

Fully Automatic/Robotic System: For large-scale production, complex geometries, and smart factory integration.

Budget Considerations

Initial Investment: High-power and robotic systems require higher upfront costs.

Operating Costs: Laser welding often reduces consumables and maintenance costs compared to TIG/MIG.

Return on Investment (ROI): Faster production speeds and less rework can lead to a quicker ROI.

If you are still unsure which industrial laser welder is best for your business, consult with ZS Laser. Our experts will analyze your materials, production scale, and budget to recommend a customized solution that maximizes efficiency and cost-effectiveness.

Customized laser welding machine

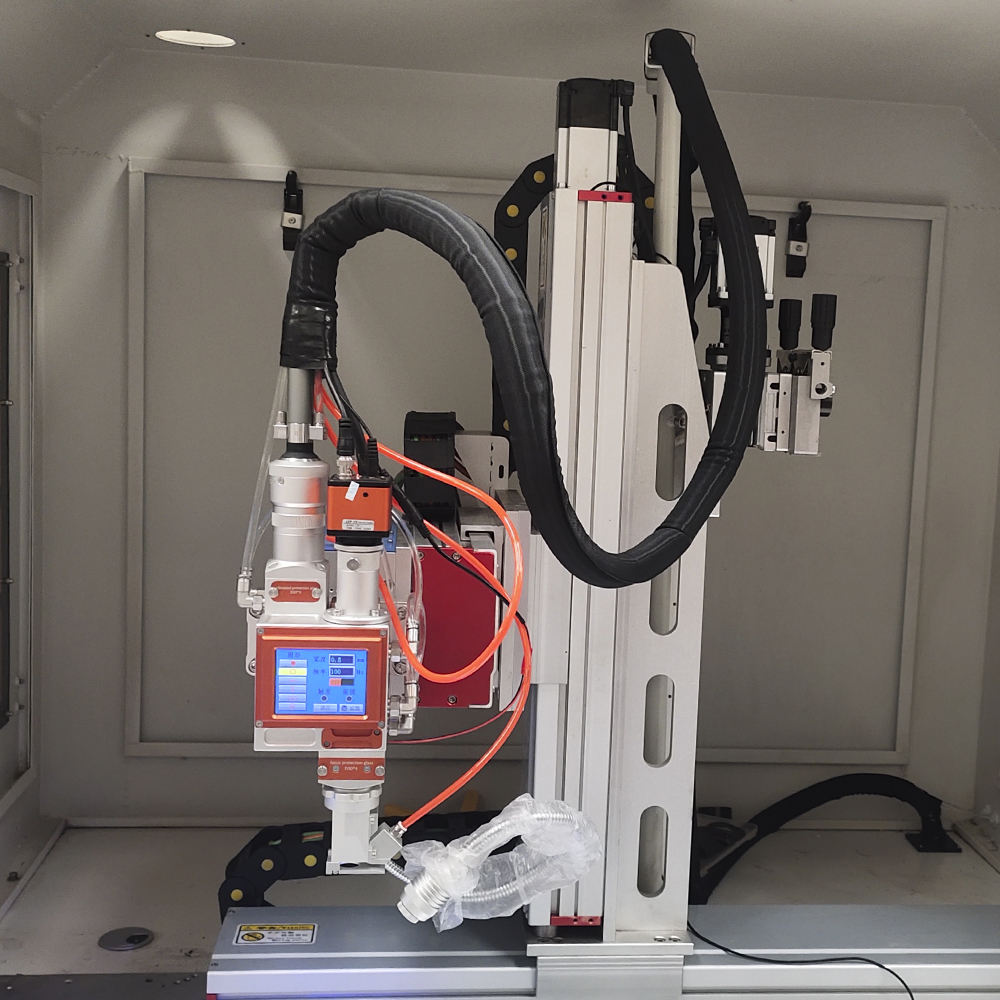

Core Components of an Industrial Laser Welding Machine

The performance of a laser welding system depends on the quality and integration of its core components:

Laser Source: Provides the high-energy beam needed for welding. Fiber lasers are the most common in modern industrial systems due to their efficiency and stability.

Beam Delivery System: Fiber cables or mirrors guide the laser beam to the welding head.

Welding Head/Optics: Focuses the beam onto the material with precision lenses to ensure welding accuracy.

Control System: The software and hardware that regulate laser parameters, motion, and automation integration.

Cooling System: Maintains the optimal temperature of the laser source and optics to ensure long-term stability.

Fixtures/Workpiece Clamping Devices: Secure parts during welding to ensure accuracy and repeatability.

Why Choose ZS Laser?

At ZS Laser, we design and manufacture laser welding machines with a strong emphasis on performance, durability, and customer-specific needs. Our advantages include:

Custom Configurations: From handheld to robotic systems, ZS Laser offers machines suitable for various industries and production scales.

Stable and Reliable Components: We use top-tier domestic brands for laser sources (MAX), optics, and cooling systems to ensure consistent performance.

Cost-Effective Solutions: Our machines balance advanced technology with affordability, making them ideal for both small-to-medium enterprises and large manufacturers.

Technical Support and Customization: Free sample welding tests, a one-year warranty, and custom-designed jigs ensure perfect integration into your production line.

By choosing ZS Laser, you are not just buying a machine; you are gaining a long-term manufacturing partner dedicated to enhancing your productivity. Contact us today for a free sample welding test and to learn more.

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.