A 3 in 1 laser welding machine is a multifunctional laser system that combines welding, cutting, and cleaning in a single unit. Instead of purchasing separate machines for each task, manufacturers can adjust the laser power, focal position, and process parameters to handle multiple operations with one device. This concept has gained market attention because it promises cost savings, space efficiency, and operational flexibility. At first glance, it seems like an all-in-one solution worth investing in. But is the reality that simple? At ZS Laser, we see things a bit differently.

At ZS Laser, our welding machines are also capable of cutting and cleaning functions. However, we do not promote this as a selling point, because while a welding machine can perform these tasks, it still falls short compared with dedicated laser cutting and cleaning machines. In the following sections, ZS Laser will outline the strengths and weaknesses of this innovative tool to help you determine whether it meets your production needs.

3 in 1 Laser Welding Maching

How Does a 3 in 1 Laser Welding Machine Work?

The concept of a 3 in 1 laser welding machine comes from the fact that welding, cutting, and cleaning all rely on the same fundamental technology: using a highly focused laser beam to deliver energy to a specific surface area. By adjusting laser power, focal position, beam diameter, and nozzle configuration, one device can switch between these functions.

Laser Welding Principle

During welding, the laser beam is focused on the joint between two work pieces. The concentrated energy creates a localized molten pool that fuses the metals together. This process ensures deep penetration, narrow weld seams, and a minimal heat-affected zone (HAZ). Welding typically requires stable power output, controlled shielding gas, and precise focusing for consistent quality.

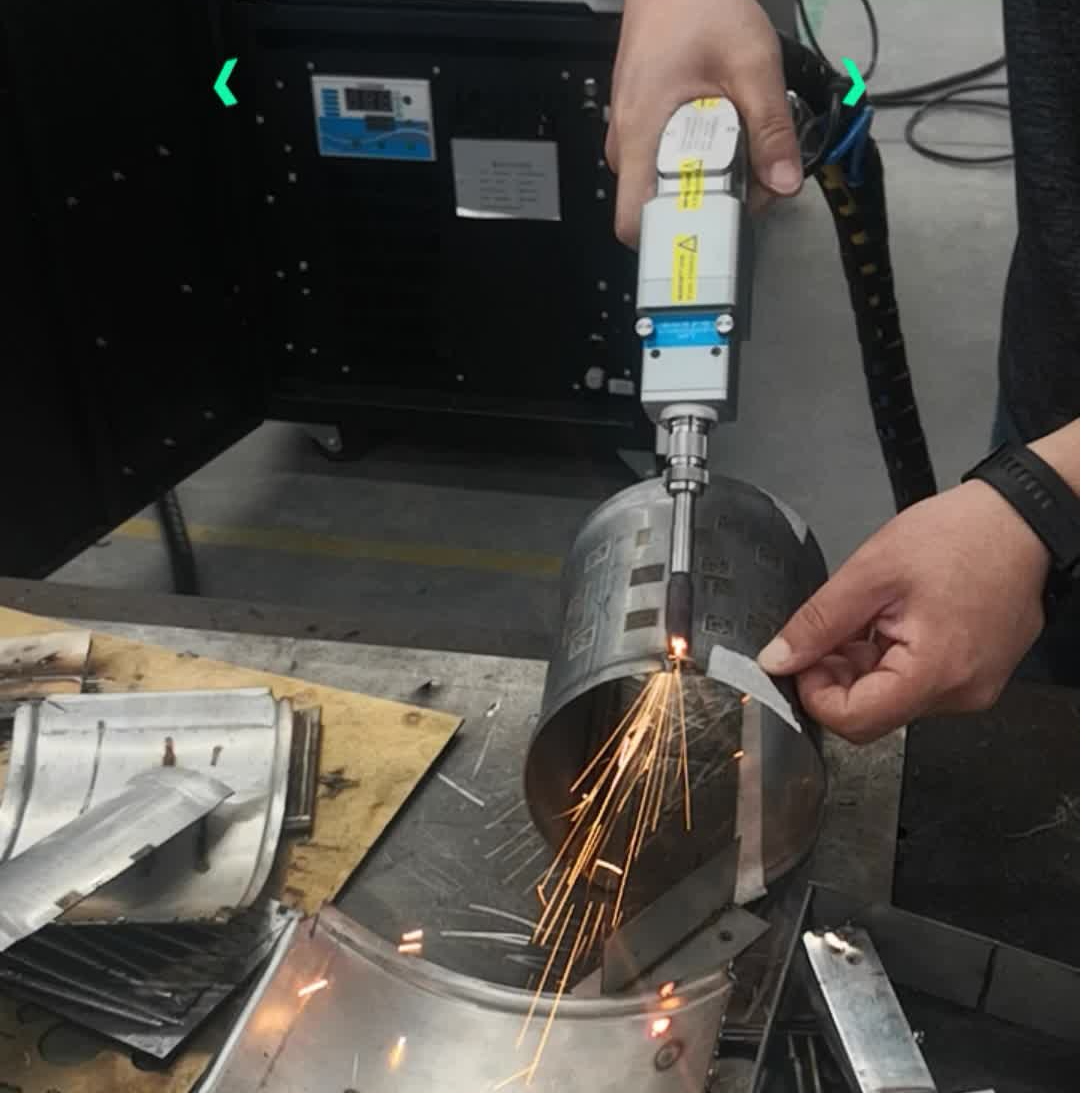

Laser Welding

Laser Cutting Principle

When configured for cutting, the laser operates at a higher energy density, melting and vaporizing material along a programmed path. Assist gas blows away molten material to form a cut. Compared with 3 in 1 systems, dedicated laser cutting machines are optimized with:

High-speed motion systems (linear motors, CNC controls) for cutting complex geometries.

Specialized optics and nozzles to ensure consistent kerf width and smooth edges.

Stable and higher power options to efficiently process thick or reflective materials.

Since welding machines are primarily designed for welding, they cannot match the accuracy, speed, or efficiency of specialized cutting systems.

Laser Cutting function

Laser Cleaning Principle

Laser cleaning uses short, high-energy pulses to remove rust, oxides, paint, or coatings from surfaces without damaging the base material. Welding lasers can achieve similar results by adjusting pulse frequency, power, and defocusing. However, dedicated laser cleaning machines are further optimized with:

Specialized pulsed laser sources designed for consistent surface ablation.

Scanning heads that cover large surface areas quickly.

Optimized wavelengths that are better absorbed by contaminants.

These optimizations ensure more efficient and uniform cleaning compared with a welding machine.

Laser Cleaning Function

Why One Machine Can Handle All Three Tasks

Because welding, cutting, and cleaning all depend on the interaction of laser energy with material, it is possible to achieve all three functions with one welding system by adjusting power, focus, nozzle, and shielding gas. While this versatility adds flexibility for small-scale jobs or emergencies, it does not replace dedicated, optimized machines for industrial-scale production.

Benefits of a 3 in 1 Machine

Despite its limitations, a 3 in 1 laser welding machine still offers notable advantages, which explains its popularity in the market.

Multi-functionality

Manufacturers—especially small workshops and repair shops—gain access to a versatile tool that can weld, cut, and clean with a single device. Instead of buying three separate systems, they can handle different tasks with one machine. This is particularly useful for low-volume production, maintenance work, or custom fabrication, where flexibility often matters more than maximum efficiency.

Cost & Space Saving

Purchasing multiple laser systems can be expensive and require significant workshop space. A 3 in 1 machine reduces the need for separate equipment and dedicated floor space, lowering initial investment and simplifying installation.

Flexibility

Switching between welding, cutting, and cleaning is relatively simple—usually requiring only parameter adjustments and nozzle changes. This allows operators to quickly adapt to different process needs, making the machine ideal for environments handling diverse, small-scale tasks on different materials.

Limitations Compared to Specialized Machines

While flexibility is the biggest strength of a 3 in 1 laser welding machine, it’s equally important to understand its limitations. In practice, these systems are best suited for welding as the main task, with occasional cutting or cleaning.

Cutting Limitations

Although a 3 in 1 machine can cut metals, its precision, edge quality, and cutting speed cannot rival that of dedicated fiber laser cutting machines. Complex geometries, thicker materials, or high-volume cutting are better handled by specialized cutting systems.

Cleaning Limitations

A welding machine can perform laser cleaning, but its cleaning coverage is limited and not optimized for continuous or large-scale use. Dedicated cleaning systems provide better beam shaping, scanning control, and efficiency for removing rust, oxides, or coatings from large surfaces.

Durability & Efficiency

Frequent switching between welding, cutting, and cleaning increases equipment stress. Using a welding system for prolonged cutting or cleaning may reduce component lifespan, strain the laser source, and raise maintenance costs.

Production Suitability

A 3 in 1 laser welding machine is well-suited for small to medium production, repair jobs, or workshops with occasional multi-process needs. However, for high-volume manufacturing, dedicated equipment offers better efficiency, reliability, and ROI.

When to Choose a 3 in 1 Machine — and ZS Laser’s Perspective

A 3 in 1 laser welding machine is most valuable in environments where flexibility outweighs specialization. Typical use cases include small-scale, customized, or multipurpose production—not mass manufacturing.

Industries where a 3 in 1 machine can be useful:

Small Repair Shops: Ideal for businesses focused on welding but requiring occasional light cutting or surface cleaning without investing in multiple machines.

Prototype Design & Custom Parts Workshops: Suitable for engineers who frequently switch between joining, shaping, and cleaning materials when developing prototypes or one-off parts.

SMEs with Diverse Needs: For small and medium-sized enterprises with limited budgets and space, multifunctional equipment helps streamline operations.

In all these cases, welding remains the primary task, while cutting and cleaning serve as supporting functions. For businesses requiring daily high-volume cutting or cleaning, dedicated machines are still the smarter investment.

ZS Laser’s Approach to Multifunctionality

At ZS Laser, our welding machines can be adjusted to perform cutting and cleaning by modifying power, focus, and process parameters. However, we don’t market this as a key selling point because we believe specialization delivers the best performance.

Our philosophy is clear:

Use welding machines for welding — ensuring deep penetration, precision, and stability.

Use cutting machines for cutting — ensuring fast speed, clean edges, and high efficiency.

Use cleaning machines for cleaning — enabling large-area coverage and consistent surface treatment.

If your production environment requires occasional cutting or cleaning in addition to welding, we can customize welding systems to meet those needs. Simply tell us your requirements, and our team will provide the right adjustments and configurations.

Whether you are looking for a professional laser welding system or exploring how a multifunctional setup could support your business, the ZS Laser team is here to help.Contact us today to discuss your needs, request a sample welding test, or explore a custom solution designed for your industry.

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.