Laser welding machines have quickly become one of the most popular tools in modern manufacturing. From kitchen and bathroom products to automotive parts, furniture, and precision hardware, laser welding is replacing traditional methods thanks to its high speed, beautiful weld seams, minimal deformation, and strong versatility. For many industries, adopting laser welding isn’t just an upgrade—it’s a competitive advantage.

But here’s the catch: the market is full of wildly different prices. Some vendors might quote just a few hundred dollars, while others offer machines that cost tens of thousands. For first-time buyers, this can be confusing—and even dangerous. Low prices often mean second-hand, refurbished, or poor-quality machines, which can lead to unstable welding, frequent breakdowns, and costly production delays.

That’s why it’s so important to understand what you’re really getting at different price points. In this article, we’ll break down the real situation behind different price levels of laser welding machines, so you can avoid falling into the “cheap trap” and make a smart, reliable investment for your business.

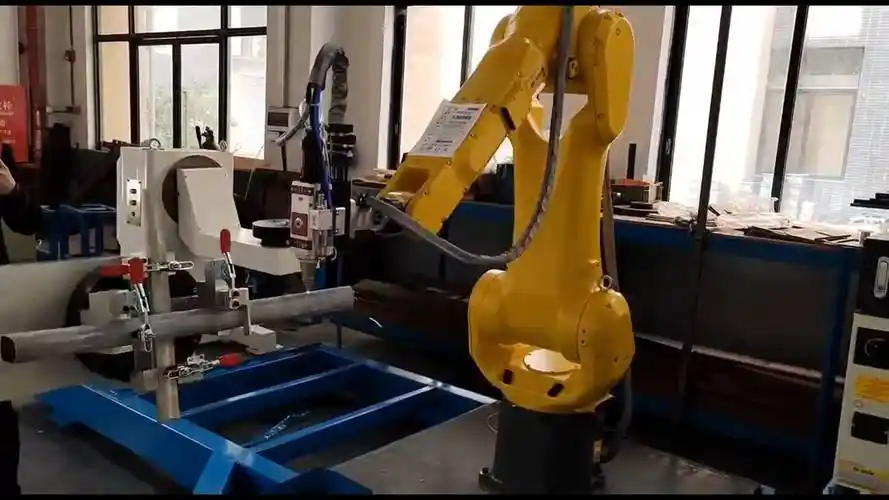

Robot Laser Welding machine

The Ultra-Low Price Trap ($300 – $1,000)

$300 Range

At this price point, you can’t even buy a reliable traditional arc welder—let alone a laser welding machine. If you ever come across a “laser welder” advertised for only a few hundred dollars, it’s almost certainly a scam or misleading promotion. A genuine laser welding machine requires precision optics, high-quality laser sources, cooling systems, and safety protections—none of which can be delivered at such a low cost.

Reminder: Be cautious. If it sounds too good to be true, it probably is.

$1,000 Range

Machines priced around $1,000 often come with hidden risks. They could be:

Second-hand or refurbished machines repackaged as “new.”

Defective units with internal issues that will break down quickly.

Products with no real after-sales support or warranty coverage.

Recommendation: Avoid being tempted by such offers. While the initial price looks attractive, the lack of reliability and service can end up costing far more in downtime, repairs, and replacement parts.

Entry-Level Price Range (~$2,200)

At around $2,200, you can finally purchase a genuine entry-level laser welding machine. These machines typically come with lower power output, making them suitable for light-duty welding tasks and small-scale production.

Suitable for:

Small factories or workshops with limited welding needs.

First-time users who want to explore laser welding without making a large upfront investment.

Limitations:

The lower power restricts the machine’s ability to weld thicker plates or handle continuous heavy-duty production.

Best suited for thin metals and smaller workpieces rather than industrial-scale applications.

Mid-to-High Power Models (~$4,200)

At around $4,200, you can get a higher-power handheld laser welding machine, with some models reaching up to 3,000W.

Suitable for:

Metal processing factories

Furniture manufacturing

Automotive parts production

Advantages:

Faster welding speed

Ability to weld thicker materials

Capable of covering most common welding requirements, making it ideal for more demanding industrial applications

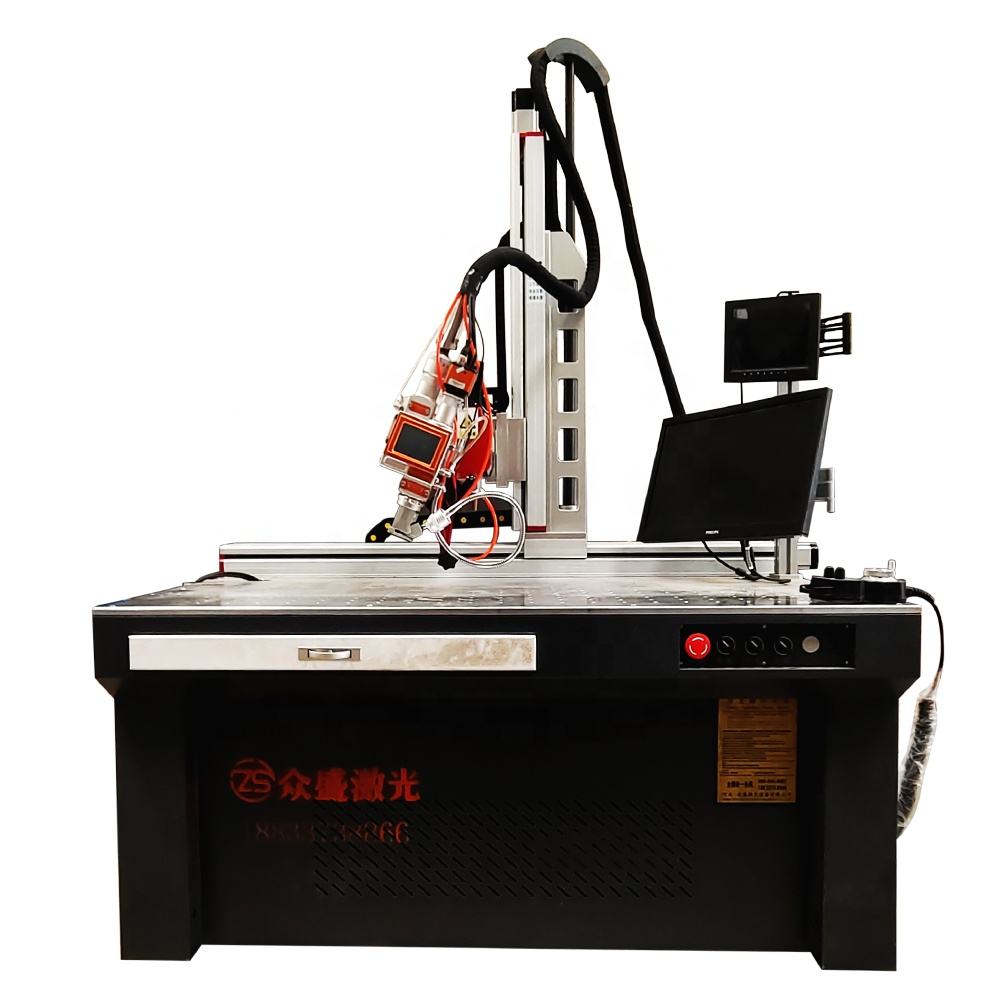

CNC Platform Models (~$8,000)

At around $8,000, you are entering the CNC platform laser welding machine category. These machines are designed for precision, repeatability, and higher production efficiency compared to handheld units.

Key Features:

Can be equipped with custom tooling and fixtures, ensuring consistent positioning and weld quality for repeated operations

Offers automated or semi-automated operation, reducing manual intervention and operator fatigue

Allows precise control of welding parameters, resulting in uniform welds and minimal rework

Suitable Applications:

Electronics manufacturing: Welding delicate metal parts or housings with high accuracy

Kitchenware production: Batch welding of stainless steel components with consistent results

Medical devices: Ensuring precise, clean welds for small or complex metal components

Advantages:

Ideal for batch production where consistent quality is essential

Reduces dependence on operator skill, making it easier to achieve high-quality welds

Can handle complex or irregular shapes that are difficult to manage with handheld machines

Full-Automatic Robot Laser Welders (~$15,000)

At around $15,000, the game changes completely. You’re stepping into the world of full-automatic robotic laser welding machines—industrial-grade systems designed to revolutionize production.

Key Features:

Equipped with robotic arms, allowing seamless integration into automated production lines

Offers high-precision welding with consistently clean seams

Extremely fast and efficient, capable of doubling production speed compared to handheld or CNC units

Ideal Applications:

Automotive manufacturing: Car frames, body panels, and precision components

Aerospace: High-precision welding for aircraft parts

Heavy machinery & engineering equipment: Large-scale, repeatable welds with minimal human intervention

Advantages:

Industrial-grade performance: built for continuous, high-volume production

Reduces labor costs and dependence on operator skill

Perfect for factories aiming to upgrade to automated welding processes, improving both efficiency and product quality

At this price point, you’re no longer just buying a welding machine—you’re investing in industrial automation and long-term production capability.

$30,000 Machines: A Story from Five Years Ago

If someone quotes $30,000 for a laser welding machine, chances are they’re sticking to prices from five years ago.

Thanks to the rapid development of China’s laser industry, production costs have dropped significantly. Machines with the same performance today are now available at much more affordable prices.

In other words: today’s buyers are luckier than those from five years ago—you can get high-performance laser welding machines without overpaying.

If you don’t know what kind of laser welding machine is suitable for you, please contact ZS Laser. We can provide you with a one-stop solution and recommend the most suitable machine according to your needs.

Contact us now to get a free welding sample test to see our machines in action with your materials.

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.