When purchasing a laser welding machine, some suppliers will promote what they claim is a “specialized welding wire” that’s essential for the machine. Without this wire, they claim, the weld won’t produce satisfactory results. However, the truth is, there’s no such thing as welding wire specifically designed for laser welding machines. Most standard welding wires are perfectly compatible with high-quality laser welding machines, including ZS laser machines. So, what exactly is welding wire? What’s the difference between single-feed and dual-feed laser welding machines? Let’s take a look.

What Is Welding Wire?

Just like in traditional welding, welding wire in laser welding is simply a filler material. It is melted by the laser beam and added to the molten pool to bridge gaps, strengthen the joint, or improve seam quality.

For small weld seams, filler wire may not be necessary; the laser itself can melt and fuse the parts directly.

For wider weld seams, however, simply melting the base material is not enough to form a strong joint. In these cases, melted filler wire is required to fill the larger gaps.

Common welding wire materials include:

Stainless steel – the most widely used, ideal for general metal welding with excellent strength and corrosion resistance.

Aluminum wire – popular for its light weight and high conductivity, but requires more precise control due to aluminum’s welding difficulty.

Brass, copper, and other alloys – used for specialized applications where conductivity or decorative finishing is important.

Wire diameters typically range from 0.8mm to 2.0mm, making them compatible with most wire feed systems used in laser welding machines. Handheld laser welding machines are generally available in two types: single-wire and dual-wire feed. Let’s take a look at the differences between the two.

Comparison of single-wire welding and double-wire welding welds

Differences Between Single Wire and Double Wire Laser Welding Machines

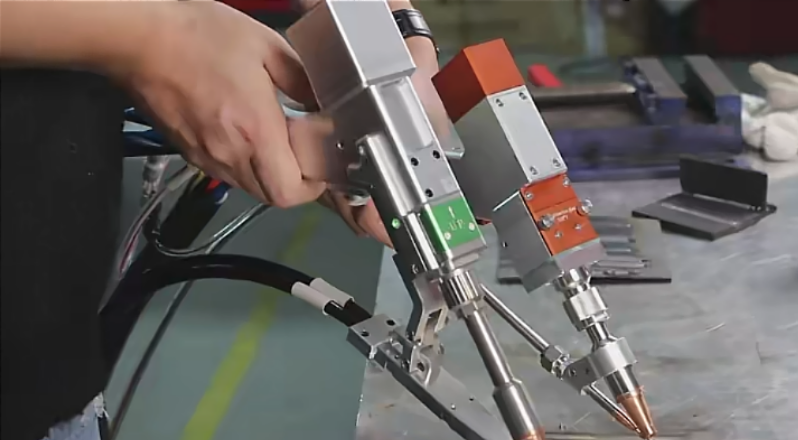

The key differences between single wire and double wire welding systems are found in the gun head, wire feeding system, and feeder design.

Welding Gun Head

Single wire gun heads are lighter and more compact, making them easier for extended operation.

Double wire gun heads are bulkier and heavier, as they house two wire feeding channels. While larger, they allow higher welding throughput compared to single wire.

Comparison between single wire feed welding gun head and double wire feed welding gun head

Wire Feeding System

Single wire machines use a standard feeder with one feeding wheel.

Double wire machines require a dedicated feeder with two feeding wheels, one on each side, to feed wires simultaneously. These systems typically support wires between 0.8 mm and 2.0 mm.

Weld Seam & Efficiency

Single wire welding produces a narrower seam, ideal for precision welding of thin plates and smaller parts.

Double wire welding produces a wider seam, suitable for larger joints, thicker plates, and applications requiring higher efficiency.

Power Requirements

Single wire machines can run effectively at lower power levels, usually 1000–1500W.

Double wire welding demands more energy. At ZS Laser, we recommend using 2000W and above for double wire systems, since lower power machines may struggle to melt both wires properly, let alone form a strong weld.

Material Thickness Compatibility

For thin plates, single wire is preferred to avoid burn-through or distortion.

For thicker plates and larger seams, double wire welding is the better choice.

How to Choose the Right Welding Wire for Your Laser Welding Machine

Some suppliers market so-called “special welding wires,” claiming only their products can achieve the best results. In reality, laser welding does not require any exclusive or proprietary wires. Standard industrial wires—whether stainless steel, aluminum, or other alloys—are fully compatible with high-quality laser welding systems.

The most important factor when selecting wire is to match it to the material of your workpiece:

For stainless steel welding → use stainless steel wire.

For aluminum alloy welding → use aluminum wire.

If you are welding copper or brass→ use corresponding filler wires.

As for wire diameter, it depends on your project needs. Simply tell us about your work piece, and our team will recommend the most suitable and cost-effective welding wire for your application.

Why Choose ZS Laser

At ZS Laser, we guide our customers in choosing the best setup—whether single wire or double wire—and provide free sample welding tests so you can see real results before making a decision. Our expert team offers professional advice, CE-certified machines, and customized solutions to help you achieve your production goals.

👉 Contact ZS Laser today to find the most efficient and cost-effective welding solution for your business.

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.