Beyond the Laser: Why Fixtures Matter

Most buyers evaluate a CNC laser welder by laser power, optics and control software. That’s necessary, but not sufficient. In real production, welding fixture design often makes the difference between a lab-quality weld and a production-ready process. Especially for CNC multi-axis laser welding — where the workpiece and laser head move relative to each other — fixtures do far more than hold parts: they define datum, enable controlled multi-axis motion, reduce distortion, and make complex, non-standard shapes weldable at volume.

A supplier who only sells machines but ignores fixtures is selling half a solution. A true partner delivers fixtures, motion strategies, and process validation so your first samples can go straight into production.

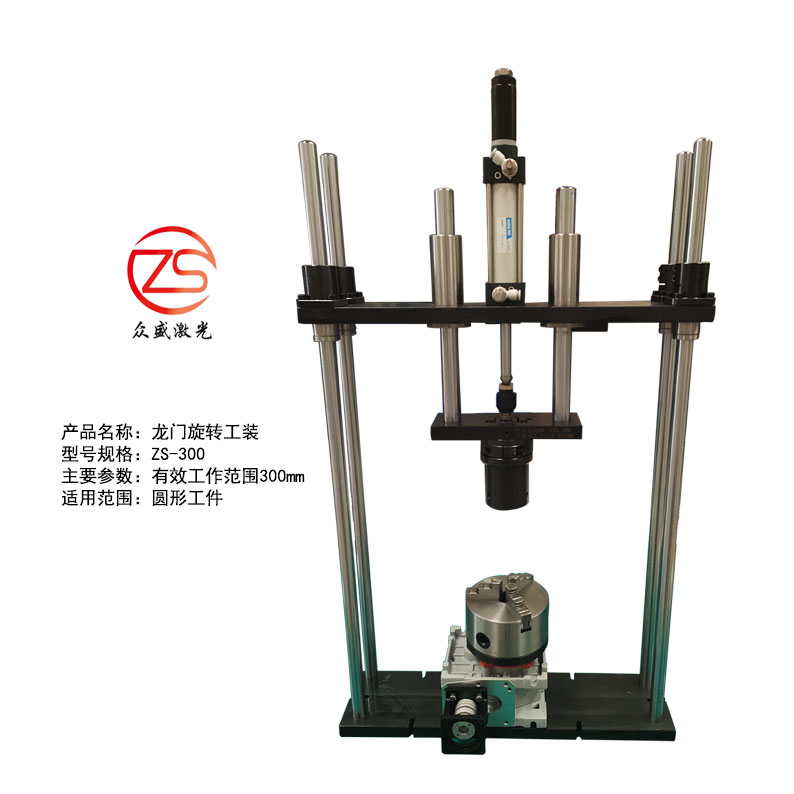

Rotary Axis Fixture

Core functions of welding fixtures in CNC laser welding

At a glance, a fixture’s job is to locate and clamp. In modern laser welding systems its functions expand to:

1.Datum and repeatability

provide precise reference surfaces so each part is presented to the laser in the exact same position.

2.Kinematic motion support

permit rotation, tilt, indexing or linear translation that the CNC controller/robot coordinates with the laser path.

3.Distortion control

hold parts in ways that reduce thermal warpage and enable stress-relieved joins.

4.Collision avoidance

ensure the laser head and sensors have safe, repeatable clearances during multi-axis moves.

5.Quick change / modularity

enable fast changeovers between part families to support small-batch manufacturing.

For multi-axis welding, fixtures become moving axes: rotary nodes, telescoping supports, and servo-driven clamps working in sync with the machine’s kinematics.

Why non-standard parts make fixture design hard — and how to solve it

Non-standard or free-form parts present multiple challenges:

Non-coplanar weld seams — welds on different surfaces require reorienting the part while keeping the weld gap, focus and incidence angle controlled.

Complex geometry — thin webs, flanges, or abrupt cross-section changes make conventional clamping impossible without deformation.

Variable tolerances — prototype or low-volume parts often have looser tolerances; fixtures must adapt without losing precision.

Solutions and design principles:

1.Multi-point datum systems. Use kinematic datum points (three contact points for location) plus secondary locators to constrain degrees of freedom without over-clamping. Kinematic coupling avoids internal stresses that can distort weld geometry.

2.Servo-driven clamps and actuators. Electric/servo clamps let you control clamping force precisely (important for thin metals) and integrate clamp motion into CNC programs. Force sensors allow closed-loop control to avoid crushing or slipping.

3.Modular locators & soft-jaws. Exchangeable soft-jaw inserts (nylon, UHMW, aluminum with compliant coatings) protect thin sections while providing repeatable location. Modular pallets permit pre-loading of fixtures offline.

4.Integrated fixturing with motion axes. For non-planar seams, incorporate rotary indexers or tilt modules into the fixture so the part moves instead of the laser head — this simplifies collision planning and maintains optimal beam incidence.

5.Thermal management design. Add heat sinks, cooling channels, or sacrificial clamps to draw heat away at critical points and reduce distortion during continuous or high-power welding.

Gantry Rotary Welding Fixture

Practical specifications and targets for high-quality fixtures

When you evaluate fixture designs, ask about measurable targets — not vague promises. Useful benchmarks:

Repeatability (positional): aim for ±0.05–0.1 mm for typical laser welding fixtures; tighter when parts demand it.

Clamping force control: servo clamps with force feedback in the range suitable for thin-wall tubing (e.g., adjustable 0–2000 N) to prevent deformation.

Indexing resolution: rotary indexers with at least 0.01° resolution for accurate seam tracking.

Fixture changeover time: modular pallets that enable sub-10-minute swaps for multi-product lines.

Cycle reliability: designed for continuous shifts with MTBF and planned maintenance schedules provided.

These are realistic, verifiable numbers that suppliers should be willing to test with your sample parts.

Motion strategies — how fixtures enable multi-axis welding

Multi-axis laser welding succeeds when motion of fixture and laser are tightly synchronized:

Synchronized motion via CNC/robotic coordination. The fixture’s servo drives or indexers should accept motion commands from the main controller (or via EtherCAT/Profinet) so the laser and part trajectory remain in phase.

On-the-fly seam tracking. Combine fixture motion with optical sensors (gap/torch-to-work distance sensors) or seam-finding cameras to correct minor positional variances during welds.

Compound trajectories. Complex seams benefit from compound motions (simultaneous rotation + linear translation). Fixtures must support these without adding backlash or vibration.

A vendor should be able to demo the actual synchronized motion sequence with your geometry before you buy.

Quick-change & modular fixturing for production flexibility

Modern manufacturing demands both precision and flexibility. Good fixture systems provide:

Palletized tooling: load fixtures offline on pallets; clamp pallets into the machine for instant job changeover.

Universal sub-plates & datum grids: enable many fixture types to use the same baseplate.

Tool-less insert replacement: reduce setup time for wear parts or geometry changes.

This approach reduces downtime and enables profitable small-batch production.

Validation: sample testing, measurement & process approval

No fixture design is complete without validation:

First-piece inspection: use CMM or laser scanners to verify datum and positional repeatability.

Weld sample qualification: run full weld cycles, measure bead geometry, penetration, microstructure (if needed), and perform mechanical tests (tensile, bend).

Thermal distortion checks: clamp instrumentation or use digital image correlation to see how parts deform during welding.

Process recipes & documentation: supplier should deliver final CNC programs, clamp force maps, sensor calibration data, and a maintenance schedule.

A serious supplier will include these steps as part of the delivery package — not as optional extras.

Choosing a supplier: what to expect from a true welding solution partner

Select a supplier who:

Offers fixture design & engineering as part of the system (not a third party).

Performs sample testing with your real parts and provides documented results.

Provides closed-loop, servo-driven fixtures with integration into the CNC/robot controller.

Delivers modular tooling & quick-change systems for production flexibility.

Supports on-site commissioning, operator training and preventive maintenance.

This is the difference between buying a machine and procuring a dependable production solution.

If you need help evaluating fixture strategies for a specific part, our engineering team can design custom fixtures, run sample welds, and deliver a turnkey welding solution — from CAD-for-Fixturing to process validation.

Contact us to discuss your workpiece and arrange a sample test. Let’s design the fixture that makes welding predictable, repeatable and profitable.

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.