As manufacturing technology continues to evolve, micro laser welding machines are becoming indispensable in industries where precision, consistency, and miniaturization are critical. Unlike traditional welding methods, micro laser welding offers extremely small heat-affected zones, superior accuracy, and the ability to join delicate or tiny components without damage.

In 2025, demand for micro laser welding is expected to surge across multiple sectors. Below we explore the top five industries where this advanced welding method is transforming production.

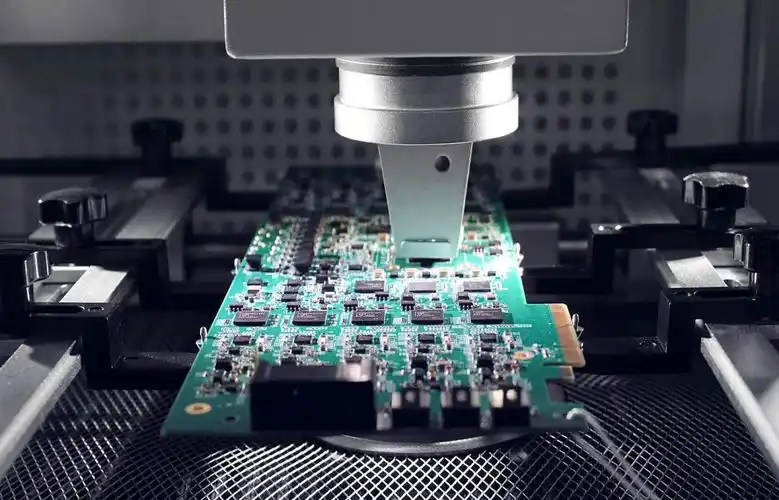

Micro laser welding machine

1. Medical Industry – Pacemakers, Catheters, and Surgical Instruments

The medical device industry is one of the fastest-growing adopters of micro laser welding machines. Products such as pacemakers, catheters, and minimally invasive surgical instruments require welds that are not only precise but also biocompatible and contamination-free.

Precision and Sterility: Micro laser welding ensures joints are smooth, burr-free, and hermetically sealed—critical for implantable devices.

Miniaturization: As medical devices shrink in size, traditional welding methods cannot provide the same level of accuracy.

Materials: Stainless steel, titanium, and nickel alloys are commonly welded with laser technology due to their strength and bio-compatibility.

With micro laser welding, medical manufacturers can improve reliability and extend the service life of life-saving devices.

2. Electronics Industry – Microelectronic Components and Sensors

The electronics sector relies heavily on micro laser welding for the assembly of microelectronic parts, sensors, and connectors. With devices becoming smaller yet more powerful, traditional joining methods are no longer sufficient.

High Precision: Micro laser welding machines can weld components at micron-level tolerances.

Reduced Thermal Stress: Sensitive chips and sensors are protected from heat damage.

Automation Friendly: Laser welding integrates seamlessly with automated production lines.

Whether it’s consumer electronics, semiconductor packaging, or advanced sensors, micro laser welding machines enable high-yield, high-accuracy production.

3. Jewelry Industry – Fine Jewelry Welding and Repair

In the jewelry industry, aesthetics are as important as strength. Micro laser welding machines provide the perfect solution for welding and repairing fine jewelry pieces, from gold and silver to platinum and palladium.

Seamless Welds: Invisible joints that preserve the design and finish of jewelry.

Delicate Repairs: Perfect for resizing rings, repairing prongs, or restoring antique jewelry without damaging gemstones.

Material Versatility: Works on precious metals with high reflectivity that are difficult to weld using conventional methods.

Jewelers worldwide are embracing micro laser welding to deliver flawless results and meet the demand for custom, high-quality designs.

4. Aerospace Industry – High-Precision Component Joining

The aerospace industry demands the highest standards in reliability and safety. Micro laser welding plays a crucial role in manufacturing and repairing critical aerospace components.

Structural Integrity: Achieves strong, lightweight welds that withstand extreme conditions.

Complex Geometries: Welds can be applied to intricate parts that are difficult to access with conventional tools.

Material Compatibility: Common aerospace materials like titanium, nickel alloys, and stainless steels can all be welded with high accuracy.

By using micro laser welding machines, aerospace manufacturers enhance durability while meeting strict international standards.

Micro Laser Welding

5. Automotive Industry – Sensors and Electronic Control Modules

As vehicles become more electrified and autonomous, the need for precise welding in automotive electronics has skyrocketed. Micro laser welding is now widely used in the production of sensors, batteries, and electronic control modules.

EV Battery Production: Micro welding ensures clean, reliable connections in battery modules and packs.

Miniaturized Components: Automotive sensors for safety systems and autonomous driving require precise, low-distortion welds.

High Throughput: Laser welding enables faster cycle times, critical for mass production.

For automakers, investing in micro laser welding machines translates into higher reliability, improved performance, and reduced warranty claims.

In 2025, micro laser welding machines are reshaping industries that demand precision and reliability. From life-saving medical devices and delicate jewelry to aerospace components and next-generation automotive electronics, micro laser welding is no longer just an option—it’s a necessity.

At ZS Laser, we understand the importance of precision welding in these industries. With over a decade of experience in laser equipment manufacturing, we provide reliable, CE-certified micro laser welding machines tailored to diverse industrial needs.

Looking to improve production with precision micro welding? Contact ZS Laser today for a free sample test and discover how our solutions can benefit your business.

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.