Many welders judge weld quality by its appearance — especially the color.Silver-white welds, golden welds, dark welds…But which weld color is actually the strongest?And can you intentionally create different weld colors using a handheld laser welder?

To answer these questions, we performed a complete welding test on 3mm stainless steel plates, using a handheld laser welder at 600W, 800W, 1200W, and 1600W.

In this article, we show you the real weld appearance, penetration results, and hammer-strike strength tests — so you can clearly understand:

What each weld color means

Why brighter welds are not always better

How welding power affects strength

How to select proper parameters for real production

Let’s dive into the results.

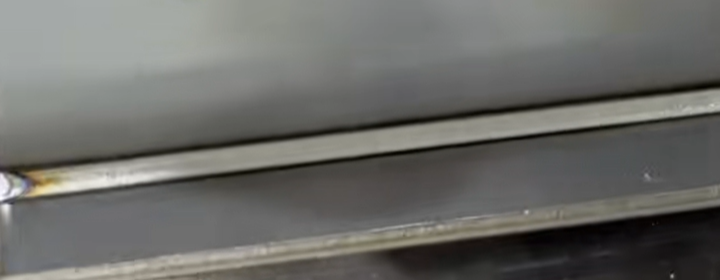

Display of front and back sides of 600W laser power welding of 3mm steel plate weld seam

600W Laser power weld 3mm steel plate color

600W laser power welding 3mm steel plate back color

As seen in the image, a 600W laser weld on a 3mm steel plate produces a beautiful bright silver-white weld, but the back of the plate shows no color change. This indicates insufficient weld penetration.

We tested this weld, and the welded component was easily broken with a single hammer blow.

This demonstrates that beautiful welds do not equal strong welds.

Insufficient power → Low penetration → Extremely poor weld strength.

Display of front and back sides of 800W laser power welding of 3mm steel plate weld seam

800W laser power welding of 3mm steel plate weld color

800W laser power welding of the back of a 3mm steel plate

We adjusted the laser welding machine power to 800W, and the result is shown in the image above. The weld is slightly yellow, and a faint yellow line appears on the back of the steel plate, indicating its penetration depth, which is slightly better than at 600W. We subsequently conducted a strength test on this weld, and the result was the same as with 600W: it broke with a single blow.

This shows that although the color is slightly darker, it is essentially still a weak weld.

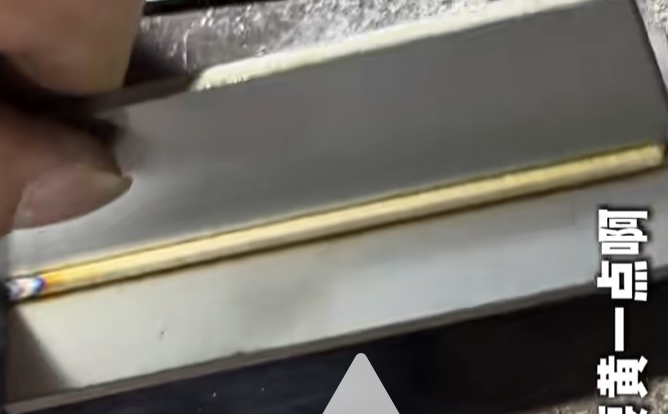

Display of front and back sides of 1200W laser power welding of 3mm steel plate weld seam

1200W laser power welding of 3mm steel plate weld color

1200W laser power welding of the back of a 3mm steel plate

We then adjusted the laser welding machine power to 1200W, and the weld color is shown in the image above. As can be seen from the image, the weld exhibits a deeper gold color, and the weld surface also shows deeper golden streaks, indicating a more stable molten pool.

After conducting strength tests on this weld, we found that even when the joint between the two steel sheets was struck forcefully, it did not break; it only deformed the steel sheets.

Conclusion: After exceeding 1000W, the weld strength significantly improved.

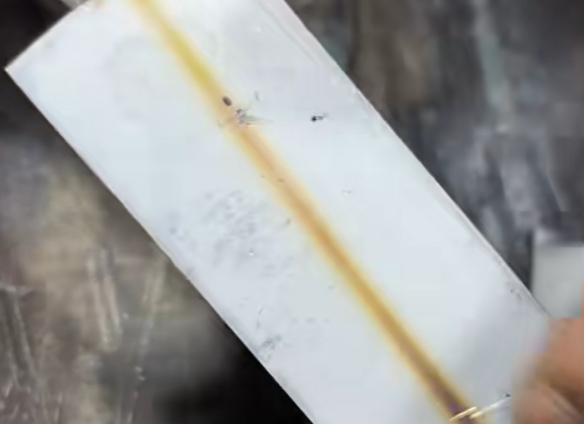

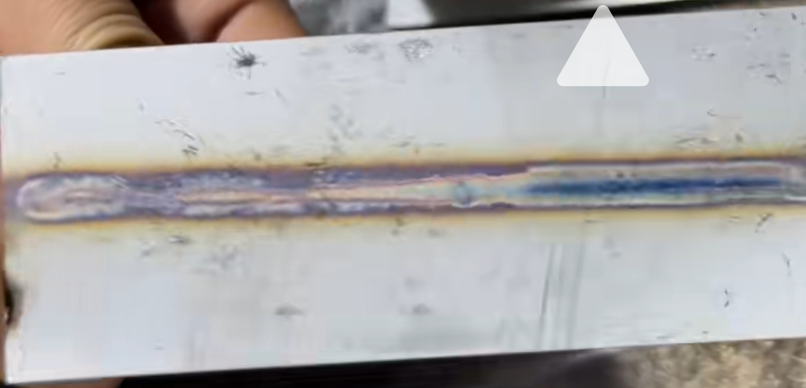

Display of front and back sides of 1600W laser power welding of 3mm steel plate weld seam

1600W laser power welding of 3mm steel sheet weld color

1600W laser power welding of the back of a 3mm steel plate

Finally, we adjusted the laser welding machine power to 1600W. As shown in the image above, the weld became deeper, and a deep golden-brown color, even tinged with black, appeared on the back of the steel plate, along with some small bumps. This indicates that the weld penetration was complete.

We also conducted a strength test with a hammer: Even with forceful hammering, the weld could not be broken; only the steel plate could be bent.

Through the above comparison, we can see that the darker the color, the stronger the melting depth, and the higher the mechanical strength.

Implications for practical welding operations

If you are welding thin plates or decorative parts, white may be sufficient.

However, for structural components, load-bearing parts, frames, and mechanical parts:

A deep gold or darker color in the weld indicates a truly high-strength weld.

A whiter weld appearance is not necessarily better.Sufficient penetration depth is key.Don’t be misled by visual effects.

Ready to Achieve Stronger, More Reliable Welds?

Weld color tells a story — but true welding quality comes from proper heat input, correct parameters, and the right equipment.

If you want:

Consistent weld penetration

Strong and durable joints

Stable performance across different materials

Expert parameter guidance for your exact application

Then it’s time to upgrade your process with professional support.

Contact ZS Laser today.

Our engineers can evaluate your material, thickness, and production needs, and recommend the ideal laser welding settings and equipment configuration.

Get expert advice, real test results, and the strongest welding performance — starting now.

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.