Platform laser welding is an advanced welding solution where the workpiece is fixed on a stable platform while the laser head moves automatically to complete the welding process with high precision. Unlike handheld laser welding, platform welding ensures consistent welding results through automation and fixture support. This makes it particularly suitable for applications that demand high precision, repeatability, and mass production, such as automotive components, electronic parts, and precision metal assemblies.

As the demand for faster production cycles and higher quality standards continues to grow in modern manufacturing, platform laser welding is becoming the preferred choice for industries that cannot compromise on welding stability and efficiency.

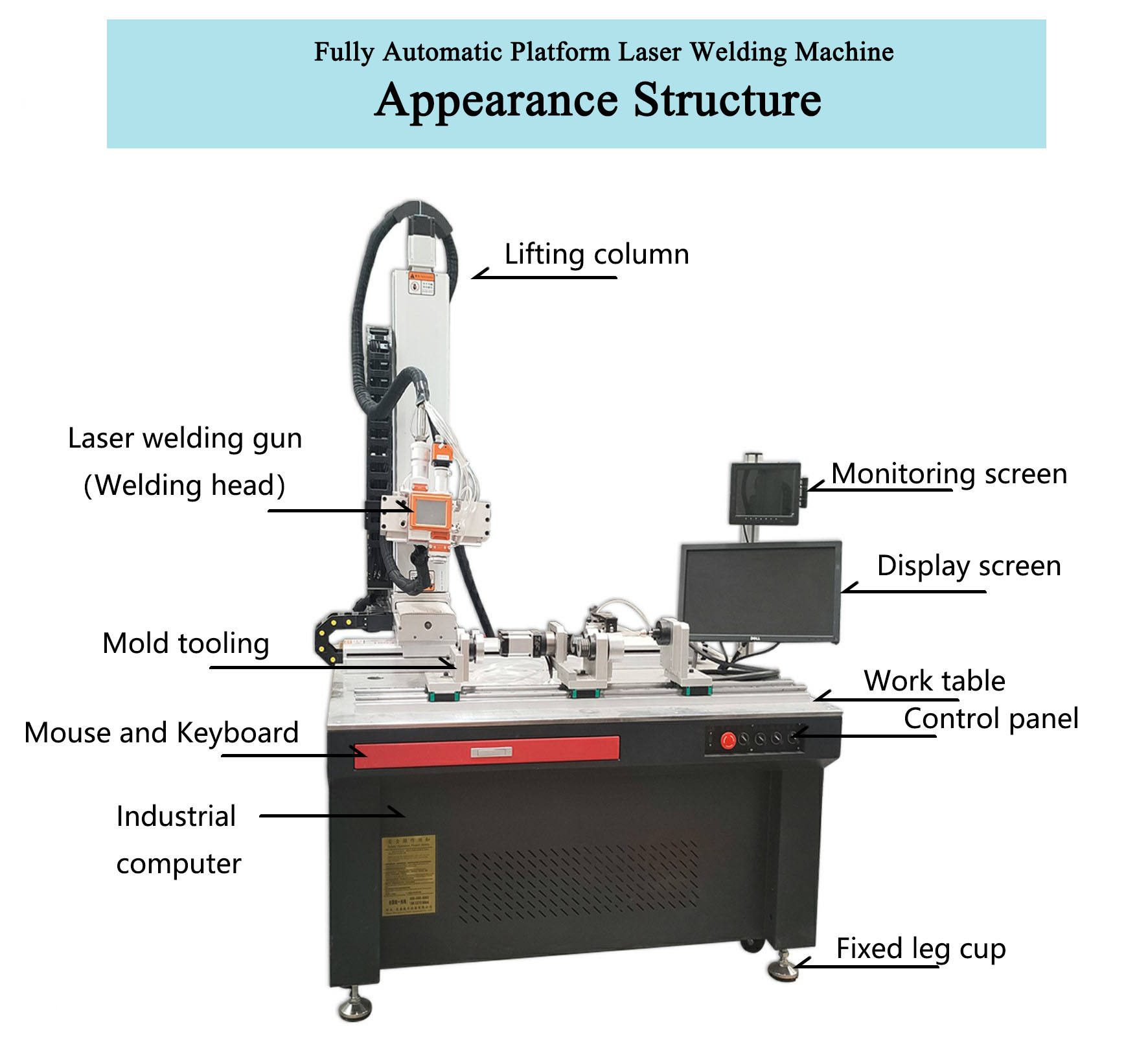

Platform laser welding machine

What is Platform Laser Welding?

Platform laser welding refers to the process in which the workpiece is fixed on a stable platform, while the laser head performs welding through automated devices such as XYZ motion tables or rotary axes. Depending on the movement direction of the laser head and fixtures, platform welding can be categorized into three-axis, four-axis, or five-axis systems. For details, you may refer to 3-Axis vs 4-Axis vs 5-Axis: How to Choose the Right Laser Welding Machine? to understand the differences.

The size and configuration of the welding platform can be customized, supporting single-station, dual-station, or multi-station designs to meet different production needs.

Key Advantages of Platform Laser Welding

High Precision & Consistency

Equipped with automated motion control systems, platform laser welding eliminates the instability caused by manual operation. Each weld can be performed repeatedly with the same parameters, ensuring uniform quality for every component. Monitoring systems can also be integrated into the platform to track weld quality in real time.

Suitable for Mass Production

Platform welding is ideal for repetitive welding tasks. Once the program and fixtures are set, the system can efficiently handle large batches of identical workpieces, reducing labor costs and improving productivity.

Versatile Fixtures

By integrating rotary axes, custom fixtures, and dedicated clamping solutions, platform laser welding can easily accommodate irregular shapes or complex geometries—something that handheld welding typically struggles to achieve.

Superior Welding Quality

Platform-based welding offers excellent penetration depth, uniform weld widths, and smooth consistency. The controlled environment minimizes defects such as porosity or undercut, resulting in stronger and more aesthetically pleasing welds.

Common Applications of Platform Laser Welding

Pipe Welding

Platform laser welding is widely used for short pipes and circumferential welds. With rotary fixtures, the system ensures smooth and uniform welds around the entire circumference—something difficult to achieve with handheld welding.

Automotive Components

From exhaust pipes and sensor housings to irregular-shaped nuts, platform laser welding provides high precision and repeatability. The automotive industry requires both strong mechanical performance and clean appearance—areas where platform systems excel.

Electronics & Battery Industry

For battery casings, metal enclosures, and various precision parts, platform laser welding ensures excellent sealing and stability. It handles thin-walled metals with minimal deformation, making it ideal for high-volume electronics and energy applications.

Medical Devices

Stainless steel tubes, miniature components, and precision assemblies in the medical field benefit from the accuracy and low heat input of platform welding. This ensures biocompatibility and structural integrity of medical devices.

Metal Enclosures & Boxes

For small housings, control boxes, and industrial enclosures, platform laser welding achieves neat and consistent seams. With dedicated fixtures, manufacturers can deliver uniform welding results across high-volume production runs.

ZS Laser Welding Machines

Platform Laser Welding vs. Handheld Laser Welding

When choosing between platform and handheld laser welding, manufacturers often need to balance precision, flexibility, and cost. Both technologies have advantages but are suited for different applications.

Precision & Consistency

Platform Laser Welding: With automated processes, it delivers exceptional precision and repeatability. Fixtures, rotary axes, and CNC worktables eliminate operator errors, ensuring uniform depth, width, and appearance of welds.

Handheld Laser Welding: While it requires relatively low operator skill compared to traditional welding, the involvement of manual operation leads to less consistency, especially for long seams or high-precision components.

Mass Production vs. Flexibility

Platform Systems: Best suited for mass production, repeatedly welding identical components with high efficiency and stable quality, while minimizing rework.

Handheld Systems: More suitable for small-batch or customized work. Operators can freely move and adjust in real time, making it ideal for repairs, irregular shapes, or prototyping.

Investment Cost & Labor Cost

Platform Laser Welding: Requires higher upfront investment in machines, fixtures, and automation. However, it reduces labor dependency and ensures long-term cost savings in high-volume production.

Handheld Laser Welding: Lower initial cost but higher reliance on labor. For mass production, inconsistency and slower pace may increase overall costs. Additionally, for complex parts, handheld welding can be time-consuming and less consistent than platform systems.

Recommended Use Cases

Platform Laser Welding: Automotive parts, electronic enclosures, batteries, pipes, and any batch production requiring high precision.

Handheld Laser Welding: Maintenance, repair, small workshops, customized metalwork, and jobs requiring high flexibility.

Case Study: Welding Special-Shaped Nuts with Rotary Axis Fixture

ZS Laser successfully completed a customer project using platform laser welding with a rotary axis fixture to weld special-shaped nuts.

The customer required mass production welding of nuts. Handheld laser welding involved frequent manual operations, resulting in low efficiency. ZS Laser designed a solution equipped with a rotary axis fixture. The nuts were securely fixed, and the laser head followed the programmed path for precise automated welding. The rotary fixture ensured smooth and accurate rotation, eliminating operator errors and guaranteeing uniform welds.The specific welding demonstration can be seen in the video below:

Results:

Fast Welding Speed: Production efficiency significantly improved compared to manual methods.

High Precision: Each nut achieved consistent penetration and weld quality.

Customer Satisfaction: The client was highly satisfied with both the welding performance and repeatability in mass production.

If you are looking for a reliable solution to enhance welding quality and efficiency, ZS Laser can provide customized platform laser welding systems tailored to your specific needs.

Contact us today for a free consultation or sample welding test, and discover how platform laser welding can upgrade your production line.

ZS Laser Equipment

ZS Laser Equipment

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.